研究開発におけるマルチフィジックスシミュレーションの具体例

さまざまな業界のエンジニア, 研究者, 科学者がマルチフィジックスシミュレーションを使用して革新的な製品の設計とプロセスを研究および開発しています. COMSOL カンファレンスで発表したテクニカルペーパーやプレゼンテーションからインスピレーションを得てください. 以下の選択項目を参照するか, クイック検索ツールを使用して特定のプレゼンテーションを検索するか, アプリケーション領域でフィルタリングします.

COMSOL コンファレンス 2020 論文集を見る

2-D Ion Transport Modelling of Water Desalination by RO System Considering the Real Membrane Effect

Modern composite membranes for reverse osmosis (RO) and nanofiltration (NF) have an ultrathin polyamide active layer (~100 nm) that performs the ion separation. Current theoretical models explain solute and water fluxes by computing concentration and potential gradients developed in one ... 詳細を見る

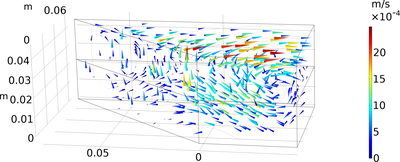

Bubble Detachment from the Surface of a (Photo)Electrode

Many (photo)electrolytic devices involve the generation of bubbles (e.g., hydrogen, oxygen). In these devices, bubble coverage on the surface of the electrode not only decreases the active area, but also induces optical loss.[1,2] Efforts in understanding the bubble detachment process ... 詳細を見る

Comparison of AEL and AEM Electrolyser Technologies

Alkaline Electrolysis (AEL) technology is known and used in industries for half a century. It is a key technology for large-scale hydrogen production powered by renewable energy for example chemical industries. Flows of 99.999% pure hydrogen up to 20’000 Nm³/h with an electrical power of ... 詳細を見る

Copper Corrosion Mechanisms by Simulation and Experiment Using Small Test Structures

Product lifetime prediction is a crucial task in microelectronics design and fabrication. Understanding of the underlying processes causing material degradation and product failure is essential for establishing accurate lifetime models. This work aims to investigate and model the ... 詳細を見る

Development of Step-by-Step Estimation Approach for Battery Simulation Based on Experimental Data.

For modeling battery simulation, material properties and simulation parameters such as electrical conductivity, diffusion coefficient, volume ratio of electrodes / electrolytes, exchange current density and electrode particle radius are required. Though these kinds information can be ... 詳細を見る

Electrochemical Impedance Spectroscopy in Carbonate Buffered Media for Biosensing Applications

Electrochemical Impedance Spectroscopy (EIS) is a technique commonly used to investigate the properties of the electrode surface and the bulk electrolyte in an electrochemical cell [1]. An AC excitation signal is applied with a frequency range, typically from 0.01 Hz to 1 MHz, and the ... 詳細を見る

Electrochemomechanical Simulations of 3D-Resolved Solid-State Lithium-Ion Battery Cells

Solid-state batteries have emerged as a viable alternative to traditional liquid-based lithium-ion batteries, offering improved cost efficiency, safety, and environmental impact. Chlorine-rich lithium argyrodite (Li6PS5Cl) has emerged as a promising solid-state electrolyte, presenting ... 詳細を見る

Evaluating Interfacial Evolution in Thin-Film All-Solid-State Lithium-Ion Battery via FEM Modeling

The advancement of battery technology plays a crucial role in achieving sustainable and electrified future with efficient energy storage. In recent years, all-solid-state lithium-ion batteries (ASSLIBs) have shown great potential, offering higher capacity, enhanced safety, and longer ... 詳細を見る

IAV’s Multi-Purpose 3D Coupling Solution for Electro-Physicochemical Battery Models via COMSOL API

The development of batteries for automotive application is progressing rapidly. It goes hand in hand with a rising demand for scarce raw materials. Diversification of cell chemistries is a promising approach to respond to market fluctuations and at the same time minimize system costs. A ... 詳細を見る

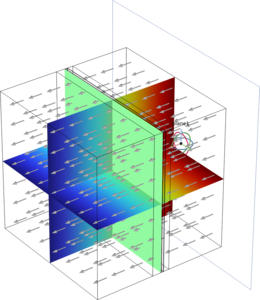

Influence of the Complexing Agent on the Throwing Power during Silver Electroplating

The throwing power is an important criterion for the industrial use of an electrolyte in electroplating applications. Using the Electrodeposition Module and COMSOL Multiphyiscs® it is possible to simulate the thickness distribution for various electroplating geometries. For a realistic ... 詳細を見る