COMSOL Day: Fluid Flow & Chemical Transport

See what is possible with multiphysics modeling

Modeling and simulation (M&S) has become an important method for fostering new ideas and designing and optimizing processes and devices in areas such as environmental technology and the chemical, food, and pharmaceutical industries. The study of transport and reaction phenomena is also relevant in the automotive and aerospace industries.

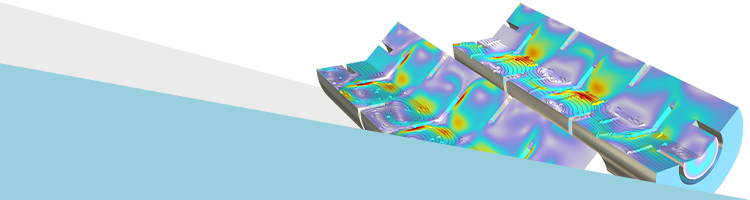

COMSOL Multiphysics® and its add-on products have become very popular in the modeling of fluid flow, chemical species transport and reactions, porous media flow, and nonisothermal reacting flow. In addition to modeling capabilities for laminar, turbulent, and multiphase reacting flows, COMSOL® features multiphysics capabilities for describing fluid–structure interaction, electrokinetic flows, and other phenomena coupled with reacting flow.

Join us for this COMSOL Day to learn more about COMSOL Multiphysics® and its add-ons for modeling transport and reaction phenomena.

Schedule

COMSOL Multiphysics® and its add-on CFD Module and Chemical Reaction Engineering Module are highly versatile when it comes to modeling and simulation involving fluid flow with chemical species transport and reactions in industries such as the bulk chemicals, specialty chemicals, pharmaceutical, biochem, consumer products, environmental tech, and petrochemical industries. The software's capabilities cover laminar and turbulent flow, multiphase flow, and nonisothermal reacting flows.

In addition to its wide range of capabilities for reacting flow, the software features unique multiphysics modeling functionality for coupling reacting flow with rotating machinery; electric fields in electrochemical cells and electrophoretic separation; as well as conjugate heat transfer with solids, fluids, and porous media. Using the Application Builder, it is also possible for modeling and simulation specialists to create simulations apps with user interfaces specialized for specific purposes, making the benefits of simulation available to a larger community of engineers and scientists within an organization.

Join us in this session to get an executive overview of the content of this COMSOL Day. We will introduce you to the functionality in COMSOL Multiphysics® for modeling fluid flow, transport of chemical species, reaction kinetics and thermodynamics, separation, mixing, multiphase flow, polymer flow, porous media flow, and heat transfer. We will also show how users have benefited from simulation apps and implementing the COMSOL® software into their processes.

The study of the impact of turbulent flows on the design of processes and devices is efficiently done using CFD. The use of COMSOL Multiphysics® and the CFD Module has become popular for these types of modeling and simulation studies.

The CFD Module features a wide range of turbulence models (9 Reynolds-averaged Navier–Stokes, or RANS, turbulence model interfaces), from the simpler algebraic models such as the algebraic yPlus model to the more advanced SST and v2-f turbulence models. In addition, the CFD Module also includes several large eddy simulation (LES) and detached eddy simulation (DES) models. All of the modeling interfaces for turbulent flow can also be coupled with other phenomena to describe fluid–structure interaction, rotating machinery, and nonisothermal flow with conjugate heat transfer, to name a few examples.

Join us in this session to get an overview of the capabilities of the CFD Module for modeling turbulent single-phase and multiphase flow.

As numerical methods and computers have become more powerful, modeling of transport and reactions has trickled down from large companies' R&D departments and national labs to almost every company and organization working with reacting systems. The Chemical Reaction Engineering Module and CFD Module, add-ons to COMSOL Multiphysics®, are widely used for analyzing reaction kinetics, thermodynamics, and reacting flows in chemical reactors, catalysts, sensors, devices for chemical analysis, and other related processes.

The modeling features provided in COMSOL® include multicomponent transport in dilute and concentrated solutions as well as reacting laminar and turbulent flows. Reaction systems can be defined simply by typing in chemical equations; the corresponding space- and time-dependent material, energy, and momentum equations are then automatically generated. This approach renders the modeling of reacting flows both uniquely efficient and user-friendly. The Chemical Reaction Engineering Module also features an extensive thermodynamics database for computing heat of reactions as well as other thermodynamic properties of liquids and gases.

Join us in this session to get an overview of the features in COMSOL® for modeling and simulating chemical reaction kinetics and reacting flows. We will discuss how to set up a model, starting with the entry of chemical equations, followed by the generation of space- and time-dependent models.

COMSOL Multiphysics® and its add-ons are widely used for understanding and designing processes and devices involving fluid flow and heat transfer. The Heat Transfer Module together with the Chemical Reaction Engineering Module is able to describe laminar and turbulent reacting flows in combination with conjugate heat transfer between solids and fluids. Heat transfer through radiation can be accounted for using surface-to-surface and surface-to-ambient methods as well as methods for heat transfer in participating media.

COMSOL® also includes unique capabilities for seamlessly coupling nonisothermal flow with conjugate heat transfer and radiation with other phenomena, such as Joule heating; thermoelectric effects (Seebeck effect, Peltier effect, and Thomson effect); and fluid–structure interaction.

Join us in this session to learn more about the features and functionality in COMSOL Multiphysics® for modeling heat transfer in fluids and solids in combination with reacting flows.

Many industrial processes are based on heterogeneous catalysis in porous media. Understanding these processes and then improving them can have great economic and environmental impacts. Modeling and simulation of reacting flow in porous media plays a key role in understanding and optimizing such processes.

COMSOL Multiphysics® and its add-on products feature a wide range of functionality for modeling of reacting flow in porous media and have therefore become popular tools in the field. The COMSOL® software also provides unique functionality for studying transport and reactions in systems with a bimodal pore structure (microporous and macroporous): so-called multiscale models.

In this session, you will learn: how multiphysics simulation enables analyses from a microscopic particle level to a macroscopic reactor level, how multiscale approaches can be used within a model to describe bimodal pore structures, and more.

Learn the fundamental workflow of COMSOL Multiphysics®. This introductory demonstration will show you all of the key modeling steps, including geometry creation, setting up physics, meshing, solving, and evaluating and visualizing results.

Processes involving multiphase flows can be efficiently understood and studied using modeling and simulation. COMSOL Multiphysics® and its add-on products include a wide range of functionality for surface tracking methods as well as dispersed multiphase flow methods.

The COMSOL® software provides tools for the level set and phase field methods for surface tracking, as well as for the moving mesh method. The dispersed multiphase flow methods include descriptions for bubbly flow, mixture, and Euler–Euler models as well as a generalized mixture model with phase transport methods.

COMSOL Multiphysics® also includes unique multiphysics modeling capabilities for studying phenomena such as the Marangoni effect, fluid–structure interaction, electrokinetic flow, and reacting flow involving multiple phases.

Join us in this session to learn more about using COMSOL Multiphysics® to model multiphase flow using surface tracking and dispersed multiphase flow methods.

Chemical sensors are characterized by their receptor and transducer mechanisms. Receptors can be based on chemisorption and physisorption as well as on bioreceptors such as enzymes and antibodies. Transducers can be based on electrochemical, optical, electronic, thermal, gravimetric, and acoustic methods.

Modeling and simulation is key to understanding and designing the processes in the receptors and transducers incorporated into sensors. As such, the COMSOL Multiphysics® software is widely used in the chemical and biochemical industries for the modeling of these devices. Its multiphysics capabilities enable the simulation of chemical reactions, diffusion and advection, fluid flow, electric and magnetic fields, thermoelectrics, electrochemistry, piezoelectricity, fluid–structure interaction, optics, acoustics, and more.

Join us in this session to learn about modeling chemical and biochemical sensors in COMSOL Multiphysics®.

In the field of polymer processing, COMSOL Multiphysics® is used to study processes such as extrusion, injection molding, resin transfer molding, and slot-die coating. Users leverage the software's modeling and simulation capabilities to optimize both their processes and the resulting parts, virtually testing the design of the processing equipment, operating conditions, and polymer properties.

COMSOL Multiphysics®, along with its add-on products, offers a broad range of modeling features for studying polymer flows and mixtures. These capabilities provide deep insights into the thermal, rheological, and chemical facets of polymer processing.

In this session, we will demonstrate how to build simulation models using COMSOL Multiphysics® and highlight various modeling features with examples relevant to polymer processing. Additionally, we will give an overview of the software’s multiphysics modeling capabilities, focusing on couplings related to fluid flow.

Separation processes are widely used in the chemical, pharmaceutical, biochemical, and food industries. These processes may include crystallization, membrane filtration and dialysis, chromatography, electrophoresis, and others.

The COMSOL Multiphysics® modeling software is often used for efficient research and development, as it includes predefined descriptions of transport phenomena, chemical reactions, and adsorption and desorption involved in separation processes. In addition, its unique multiphysics capabilities allow for modeling of arbitrary physics phenomena coupled to transport and reaction phenomena, such as the effect of stresses and strains on porosity, and the impact of electric fields on the migration of charged ions and particles.

Attend this session to learn about using COMSOL Multiphysics® to simulate a range of separation processes, from crystallization in bulk chemical production to transport and adsorption in membranes for fine chemical production.

Tank reactors and mixers equipped with impellers are often used for production in the fine chemical, food, and pharmaceutical industries. For larger flow rates of bulk chemicals, static mixers can also be used. Modeling and simulation are valuable to the process of selecting tank designs, baffles, impellers, blades in static mixers, and operating conditions that meet product quality and production rate requirements. COMSOL Multiphysics®, the CFD Module, and the Mixer Module are often used for these purposes in the industry. In addition to its fluid flow modeling capabilities, the software also includes unique multiphysics capabilities for the modeling of reacting flow, conjugate heat transfer, and fluid–structure interaction.

Join us in this session to learn more about the use of COMSOL Multiphysics® for the modeling and simulation of mixers with multiphase flow, reacting flow, and conjugate heat transfer, for both laminar and turbulent flow.

Register for COMSOL Day: Fluid Flow & Chemical Transport

To register for the event, please create a new account or log into your existing account. You will need a COMSOL Access account to attend COMSOL Day: Fluid Flow & Chemical Transport.

For registration questions or more information contact info@comsol.de.

COMSOL Day Details

June 6, 2024 | 10:15 CEST (UTC+02:00)