Welcome to the COMSOL Image Gallery. The simulation images on this page are available for

editors and journalists to use in appropriate articles. The phrase "Image made using COMSOL

Multiphysics® software and provided courtesy of COMSOL." must appear in the vicinity of every image

or at the bottom of the article.

For all other uses you must contact COMSOL directly through www.comsol.com/contact/

or by writing to .

COMSOL Multiphysics Version 4.3

|

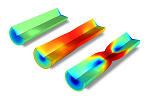

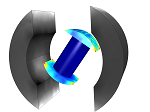

Bar NeckingIn this classic benchmark, a circular bar is subjected to a uniaxial tensile test, resulting in large deformations. The bar experiences large-scale necking and plastic deformation across its central cross-sectional region. This simulation is made possible by the large strain plasticity option available in the Nonlinear Structural Materials Module and the new, very powerful Double Dogleg solver.

|

|

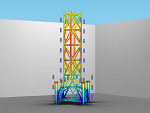

Oil Platform CorrosionAn oil rig structure immersed in seawater is protected by 52 sacrificial aluminum anodes. Before deploying the anodes, engineers would use the new COMSOL Multiphysics Corrosion Module to optimize the position of each anode for the best possible corrosion protection. Visualized is the electrolyte potential on the surface of the structure.

|

|

Galvanic CorrosionGalvanic corrosion of a magnesium alloy (AE44) connected to mild steel in a salt-water solution. The electrode material removal is represented by a moving mesh and can thus be considered as a process variable.

|

|

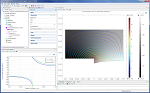

Injection MoldingCooling of a steering wheel injection mold. The new COMSOL Pipe Flow Module allows for efficient simulation of the cooling channels using 1D pipe non-isothermal flow. This is fully coupled to the heat transfer simulation of the mold and polyurethane part, which was imported as a CAD geometry.

|

|

Fast MeshingThis geometric representation of a lung was imported using the COMSOL CAD Import Module. The meshing algorithm creates a default mesh in 30 seconds on a standard dual core workstation. Generating a coarser mesh takes 10 seconds, when Virtual Geometry operations are applied to minimize the influence of non-essential geometry edges and surfaces. Geometry courtesy of Prof. Thomas Royston and Ying Peng, Acoustics & Vibrations Laboratory, University of Illinois at Chicago.

|

|

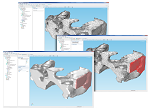

Boundary Selection from MeshThis nanotomography model of a lithium-ion battery microstructure was imported as a mesh. For enabling a boundary condition on one side of the structure, COMSOL 4.3's new Mesh Selection operations can group elements into a new geometrical boundary. This technique allows for importing previously meshed structures, including legacy meshes, which can then can be used for any type of COMSOL Multiphysics simulation. The meshed model seen here is courtesy of Professor Likun Zho’s research group at Indiana University-Purdue University, Indianapolis.

|

|

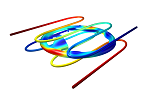

Brushed DC MotorThe AC/DC Module now includes the ability to model rotating machinery in 3D. Here, a brushed DC motor simulated with the new 3D rotating machinery user interface is shown. Visualized are B field, coil current, axial torque, and rotational angle.

|