Failure Prediction in a Laminated Composite Shell

Application ID: 65641

Laminated composite shells made of carbon fiber reinforced polymer (CFRP) are common in a large variety of applications due to their high strength-to-weight ratio. Evaluation of the structural integrity of a laminated composite shell for a set of applied loads is necessary to make the design of such structures reliable.

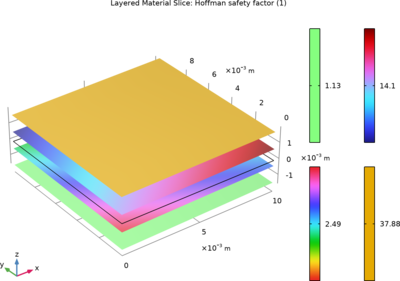

The structural integrity of a laminate with different fiber orientations in each ply is assessed through the parameters called Failure Index and Safety Factor, using different polynomial failure criteria. Because of the orientation, each ply will have different stiffness in the longitudinal and transverse directions, and hence different responses to the loading. The analysis using a polynomial failure criterion is termed first ply failure analysis, where failure in any ply is considered as failure of the whole laminate.

This example shows how to model laminated composite shells using the Shell interface together with the Composite Materials Module. In this example, six different polynomial criteria are compared. This model is a NAFEMS benchmark model, described in Benchmarks for Membrane and Bending Analysis of Laminated Shells, Part 2: Strength Analysis. The COMSOL Multiphysics solutions are compared with the reference data.

この model の例は, 通常次の製品を使用して構築されるこのタイプのアプリケーションを示しています.

ただし, これを完全に定義およびモデル化するには, 追加の製品が必要になる場合があります. さらに, この例は, 次の製品の組み合わせのコンポーネントを使用して定義およびモデル化することもできます.

- COMSOL Multiphysics® and

- 複合材料モジュール and

- 構造力学モジュール

アプリケーションのモデリングに必要な COMSOL® 製品の組み合わせは, 境界条件, 材料特性, フィジックスインターフェース, パーツライブラリなど, いくつかの要因によって異なります. 特定の機能が複数の製品に共通している場合もあります. お客様のモデリングニーズに適した製品の組み合わせを決定するために, 製品仕様一覧 を確認し, 無償のトライアルライセンスをご利用ください. COMSOL セールスおよびサポートチームでは, この件に関するご質問にお答えしています.