アプリケーションギャラリには電気, 構造, 音響, 流体, 熱および化学分野に関連する COMSOL Multiphysics® チュートリアルおよびデモアプリファイルが用意されています. これらの例はチュートリアルモデルまたはデモアプリファイルとそれに付随する手順をダウンロードすることにより独自のシミュレーション作業の開始点として使用できます.

クイック検索機能を使用して専門分野に関連するチュートリアルやアプリを検索します. MPHファイルをダウンロードするには, ログインするか, 有効な COMSOL ライセンスに関連付けられている COMSOL Access アカウントを作成します. ここで取り上げた例の多くは COMSOL Multiphysics® ソフトウェアに組み込まれ ファイルメニューから利用できるアプリケーションライブラリからもアクセスできることに注意してください.

This example models the temperature profile in a liquid-cooled prismatic battery pack during a high-rate charge. The pack consists of 16 prismatic battery cells connected by busbars, placed on an aluminum plate containing four cooling channels. The battery pack is assumed to have two ... 詳細を見る

This model simulates a static analysis of heat conduction in a thin conductive shell. This is a benchmark model where the result is compared with a NAFEMS benchmark solution. 詳細を見る

The heat exchanger in this tutorial model contains a dynamic wall with an oscillating wave shape. The deformation induces mixing in the fluid and reduces the formation of thermal boundary layers. Hence, it increases heat transfer between the walls and the fluid. In addition, the wave ... 詳細を見る

This example shows how to set up multiple sandwiched thin layers with different thermal conductivities in two different ways. First, the composite is modeled as a 3D object. In the second approach, the thin domains are modeled with thermal resistors in the Lumped Thermal System ... 詳細を見る

This tutorial model uses a heat sink geometry from the Part Library. The tutorial shows different approaches to heat transfer modeling when studying the cooling of an electronic chip. In the first part, only the solid parts are modeled, while the convective airflow is modeled using ... 詳細を見る

This example is a variant of the Composite Thermal Barrier tutorial and shows how to set up multiple sandwiched thin layers with different thermal conductivities in two different ways. First, the composite is modeled as a 3D object. In the second approach the Lumped Thermal System ... 詳細を見る

This example is a model of a continuous casting process. Liquid metal is poured into a mold of uniform cross section. The outside of the mold is cooled and the metal solidifies as it flows through. When the metal leaves the mold, it is completely solidified on the outside, but still ... 詳細を見る

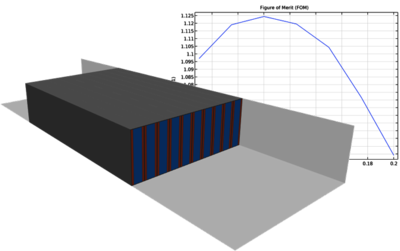

This example computes the effectiveness of a porous microchannel heat sink over a conventional microchannel heat sink. The model is fully parameterized. A parameter study on the thickness of the porous substrate is used to determine the optimal configuration. 詳細を見る

Maximizing product yield is a main task in chemical reaction engineering. This can be especially challenging if the desired product, once formed, can be consumed by further reactions. This example investigates such a series reaction as it occurs in a tubular reactor. You will start by ... 詳細を見る

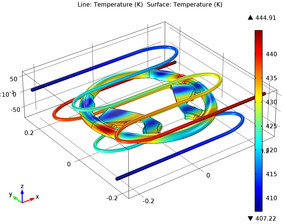

This model shows how you can use the Non-Isothermal Pipe Flow interface together with the Heat Transfer in Solids interface to model the cooling of a injection molded polyurethane part for a car steering wheel. The equations describing the cooling channels are fully coupled to the heat ... 詳細を見る