3D Modeling of Nanocomposites

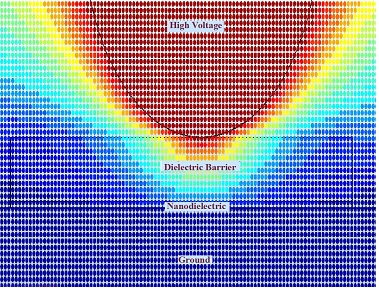

Current research focus on improvement of electrical, mechanical, surface characteristics of polypropylene films by incorporation of nanoparticles into the polymer matrix of the film. We built 3D model of polypropylene Nanocomposites made of polypropylene matrix and incorporating various nanoparticles within polymer matrix. The purpose is to simulate multiphysics such as electromagnetic field and space charges internal to the Nanocomposites. We also investigated how nanoscale interface zone influenced space charge behavior of the polypropylene Nanocomposite material. Polypropylene is widely used in power industry as insulation. When polypropylene is used in power apparatus, under the application of high voltage (up to 30kV), the insulation suffers from various issues such as internal materials degradation, space charges, partial discharges, electrical treeing, insulation breakdown etc. Space charges distorts applied electric field, and when maximizes it introduce complex partial discharges inside and outside the insulating materials. This partial discharge starts electrical treeing and ultimately causes breakdown of the insulation. And this causes power failure in real life application and instability happens. So, we incorporated nanoparticles (both organic montmorrilonite clay and inorganic tetrasilisic fluro mica) into the polymer matrix homogeneously using melt compounding method. Nanoparticles form an interface zone between nanofiller and polymer matrix. Nanoscale physical property of these particles approximately eliminates traps, space charges and prevent materials breakdown and increase breakdown strength. Thus nanoparticle increases the lifetime of insulation under high voltage. Besides doing experiments we did 3D modeling in COMSOL Multiphysics® to investigate nanoscale phenomena.

ダウンロード

- Rab_COMSOL_POSTER.pdf - 0.68MB

- PPTRESEARCH_RAB.pptx - 2.39MB

- COMSOL_PAPER_MA _RAB.pdf - 0.6MB