研究開発におけるマルチフィジックスシミュレーションの具体例

さまざまな業界のエンジニア, 研究者, 科学者がマルチフィジックスシミュレーションを使用して革新的な製品の設計とプロセスを研究および開発しています. COMSOL カンファレンスで発表したテクニカルペーパーやプレゼンテーションからインスピレーションを得てください. 以下の選択項目を参照するか, クイック検索ツールを使用して特定のプレゼンテーションを検索するか, アプリケーション領域でフィルタリングします.

COMSOL Conference 2024 論文集を見る

Marangoni flow affects the heat and mass transfer occurring in the molten metal regions in welding and additive manufacturing processes. It originates from the surface tension gradient (∂γ/∂T) induced at the melt pool surface due to the temperature difference. The flow pattern within ... 詳細を見る

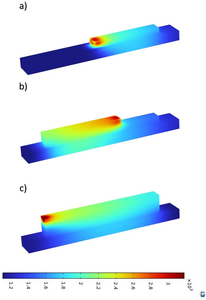

Introduction Numerical modeling of melt-casting is becoming a popular tool for the energetic materials and explosives industry. Compared to traditional metal casting, the cooling cycle for explosive melts is significantly longer because of their high Prandtl numbers [1]. Improving the ... 詳細を見る

Laser cutting process is usually employed in machining process, however it is also applied for dismantling nuclear facilities. Contrary to mechanical processes where tools wear out quickly and are often renewed, laser cutting process is a contactless approach, therefore there is no ... 詳細を見る

Arc plasma can heat and melt the metal material and flows of molten metal can be affected by several forces such as Lorentz force which is ruled by current, Marangoni force controlled by surface tension, buoyancy force, and arc drag force. Usually, surface tension variation is determined ... 詳細を見る

Laser drilling of titanium and its alloys is widely used in aerospace industry, as it offers selective removal of material at high accuracy and speed. However, laser drilling often inherits defects such as large heat affected zone, micro cracks and recast layer. These defects depend upon ... 詳細を見る

Additive manufacturing gathers technologies where near net shape components are produced by depositing successive layers of materials. Among these technologies, the Layer Beam Melting (LBM) process – often referred to as Selective Laser Melting (SLM) – is garnering industrial interest, ... 詳細を見る

Present work is done in the framework of the SisAl Pilot EU project, which aims at optimising the silicon production in Europe by recycling materials and using a carbon-emission friendly technology. The silicon production experiments are conducted on laboratory and pilot scales in ... 詳細を見る

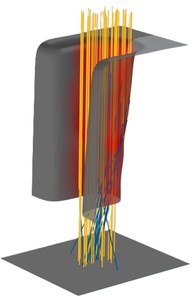

The Laser Metal Deposition process (LMD) is a rapid free form fabrication method which can be used to manufacture new near net shape metallic components, to repair used ones or to add functional parts on existing ones. This process is composed by multiple gas streams flowing inside a ... 詳細を見る

In this paper, we present a study of the simulation of Directed Energy Deposition (DED) Additive Manufacturing (AM) using a multiphysics approach. We use a combination of Heat Transfer in Fluids, Solid Mechanics and Laminar Flow physics to accurately simulate the DED process. The ... 詳細を見る

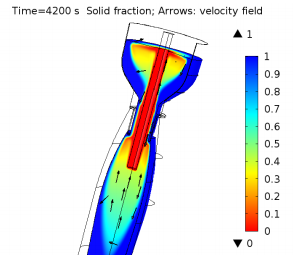

A solidification process of casting explosives in shell is studied in this paper. An enthalpy method approach is used to model the solidification process. Both the thermal and mechanical effects are taken into account. An ALE (Arbitrary Lagrangian-Eulerian) method is used to represent ... 詳細を見る