研究開発におけるマルチフィジックスシミュレーションの具体例

さまざまな業界のエンジニア, 研究者, 科学者がマルチフィジックスシミュレーションを使用して革新的な製品の設計とプロセスを研究および開発しています. COMSOL カンファレンスで発表したテクニカルペーパーやプレゼンテーションからインスピレーションを得てください. 以下の選択項目を参照するか, クイック検索ツールを使用して特定のプレゼンテーションを検索するか, アプリケーション領域でフィルタリングします.

COMSOL Conference 2024 論文集を見る

Here we investigate a promising passive cooling method through making advantage of the unique properties of ferrofluid. When a magnetic dipole or a permanent magnet is put at the hot side of a system, it will attract the cold ferrofluid to the hot place and displace the hot ferrofluid ... 詳細を見る

A successful development of an effective quench detection and protection method for a high temperature superconducting (HTS) coil based on a HTS coated conductor tape lays on a thorough understanding of its slowly propagating, three-dimension (3D) quench behavior. Toward this goal, a 3D ... 詳細を見る

Technological processes in the engineering practice from point of view of systems and control theory are frequently in the form of distributed parameter systems (DPS). Techniques of FEM based modeling and design of control synthesis methods of DPS which is acceptable for various ... 詳細を見る

The present study focuses on the design and analysis of a single-engine, propeller-driven general aviation airplane. Initial weight estimation based on the initial sketch and the design mission profile is conducted. The estimated weight and other design parameters are used to define the ... 詳細を見る

Precise physics experiments in space require highly stable thermal environments, especially if the experiments are targeted in earth orbits where eclipses will cast large temperature variation. We have been designing and modeling a thermal system with sub micro-kelvin stability using ... 詳細を見る

The main objective of the present work is to perform stress analysis on composite laminates under unaxial/biaxial loading to serve as a preliminary data for test verification. A detailed calculation based on the Classical Lamination Theory was performed for a laminate. The material used ... 詳細を見る

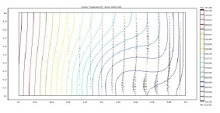

This paper illustrates how to set up and solve a two-dimensional flow problem having dimensions of 640 x 320 micro-meter using the Navier-Stokes equations with the help of COMSOL Multiphysics solver. The principle of our pore-scale modeling approach is composed of two steps. The first ... 詳細を見る

In order to provide swift and precise diagnostics, physicians and medical doctors require an adequate amount of information about the patient\'s condition. An integrated SPR (surface plasmon resonance) biosensing platform is currently developed by our research group with the aim of ... 詳細を見る

In this paper we compare the results from a bending cantilever beam experiment with the theoretical values and COMSOL finite element simulation results. In the experiment a simple cantilever beam with a hole is loaded at the end. Measurements are recorded by four strain gauges mounted on ... 詳細を見る

Isogrid plate components are widely used in aerospace structures because of their greater stiffness to weight ratios compared with thicker plates of the same material. Isogrid plates consist of flat plates conjoined with thin ribs in specific geometric patterns. The purpose of this study ... 詳細を見る