研究開発におけるマルチフィジックスシミュレーションの具体例

さまざまな業界のエンジニア, 研究者, 科学者がマルチフィジックスシミュレーションを使用して革新的な製品の設計とプロセスを研究および開発しています. COMSOL カンファレンスで発表したテクニカルペーパーやプレゼンテーションからインスピレーションを得てください. 以下の選択項目を参照するか, クイック検索ツールを使用して特定のプレゼンテーションを検索するか, アプリケーション領域でフィルタリングします.

COMSOL Conference 2024 論文集を見る

In the field of laser applications, surface treatment is highly studied. Two process categories are commonly used. First processes use very short pulses (femto or pico seconds) known to avoid thermal effects and to have high spatial resolutions. Second processes have higher interaction ... 詳細を見る

Here we present a simulation for evaluation of novel obscurant candidates under high-energy laser (HEL) illumination. This approach incorporates thermal modeling into obscurant characterization, allowing for evaluation of the temperature increase of the candidate obscurants as well as ... 詳細を見る

Laser technologies such as welding, cutting and metal deposition are widely used in the industry. High quality requirements regarding process products cause that there is often a need to monitor the process. For this purpose, optical sensors integrated with a laser head are often used. ... 詳細を見る

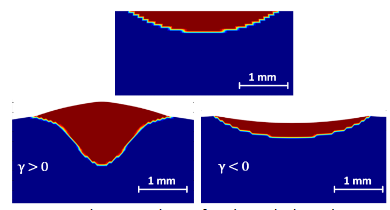

A lateral observation of laser-induced keyhole through the quartz window is an easy and cheap experimental method. It opens an interesting perspective for the study of keyhole asymmetry in case of dissimilar metal combinations. To quantify the effect of quartz window on the observed ... 詳細を見る

1.Introduction Transparent conductive oxides (TCOs) operating near their epsilon-near-zero (ENZ) point have recently been shown to exhibit strong and ultrafast intraband optical absorption processes, whose excitation results in a variation of the effective mass and electrical conductance ... 詳細を見る

Whereas the physic models of fluid lubrication should be able to provide quantitative predictions to industrial problems, it is somehow demanding to provide the input data to feed these high-level equation systems. The operating conditions are generally available, and the material ... 詳細を見る

This study presents a combined simulation and experimental investigation of mixing performance in a batch mixer, with the goal of validating simulation results and identifying optimization potential. The focus is on evaluating mixing times and flow fields to enhance process efficiency, ... 詳細を見る

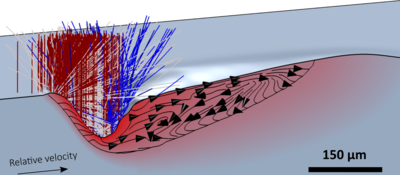

The present work introduces a new methodology, based on COMSOL Multiphysics® Application Builder, to account for the “beam trapping” effect in multiphysical modelling of laser welding. Incident intensities involved in laser welding processes are high enough to induce material ... 詳細を見る

Laser surface texturing has emerged as a promising texturing technique due to properties such as excellent repeatability, non-contact process, the ability to achieve small-size features and high-quality finishing. The work described here is part of the H2020 research program called SHARK ... 詳細を見る

New emerging trends in the MEMS market are linked to the availability of small, reliable and miniature sensors for harsh environment applications to increase penetration in all application fields, considering very wide operating condition ranges. These trends are pushed forward by the ... 詳細を見る