- COMSOL News 2025

- COMSOL News Special Edition: Food Industry

- COMSOL News 2023

- COMSOL News 2022

- COMSOL News 2021

Optimized Heating Process with Uniform Coating

Mika JudinRautaruukki Oyj

Hämeenlinna, Finland

Rautaruukki Oyj supplies metal-based components and systems to the construction and mechanical engineering industries, where process engineer, Mika Judin, works with optimizing their coating technologies. When coating rolled metal with paint, it is important that the coating be applied such that it is not discolored or damaged, and that it is applied evenly. Heat transfer therefore needs to be fully understood.

Judin used COMSOL Multiphysics to determine the heat conductivity of the paint during the drying process in a 3D model and then, with this information, to model the whole oven drying process. The models considered heat transfer, a liquid-to-vapor phase change, and a liquid-to-solid phase change.

His analyses made it possible to fine-tune oven setups and provide feedback to paint manufacturers. Using his models, he was also able to achieve a high degree of product uniformity and quality throughout the shifts run by different operators.

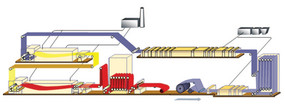

Outline depiction of the color coating process. The coating is applied where the strip is a yellow color, while the oven zones are where the strip is a red color.

Outline depiction of the color coating process. The coating is applied where the strip is a yellow color, while the oven zones are where the strip is a red color.

ダウンロード

- Ruukki_CN12.pdf - 0.98MB