アプリケーションギャラリには電気, 構造, 音響, 流体, 熱および化学分野に関連する COMSOL Multiphysics® チュートリアルおよびデモアプリファイルが用意されています. これらの例はチュートリアルモデルまたはデモアプリファイルとそれに付随する手順をダウンロードすることにより独自のシミュレーション作業の開始点として使用できます.

クイック検索機能を使用して専門分野に関連するチュートリアルやアプリを検索します. MPHファイルをダウンロードするには, ログインするか, 有効な COMSOL ライセンスに関連付けられている COMSOL Access アカウントを作成します. ここで取り上げた例の多くは COMSOL Multiphysics® ソフトウェアに組み込まれ ファイルメニューから利用できるアプリケーションライブラリからもアクセスできることに注意してください.

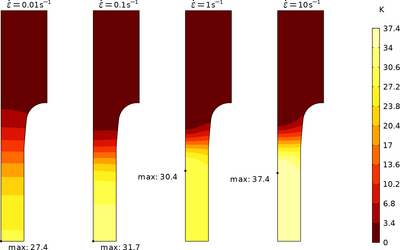

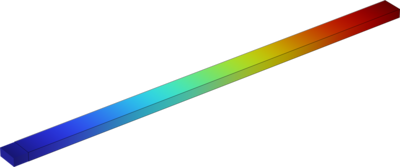

In this example, a tensile test is simulated at four different strain rates. The Johnson–Cook hardening law is used to model the strain rate dependency of the plastic hardening. The temperature distribution and thermal expansion caused by the heating generated by the plastic ... 詳細を見る

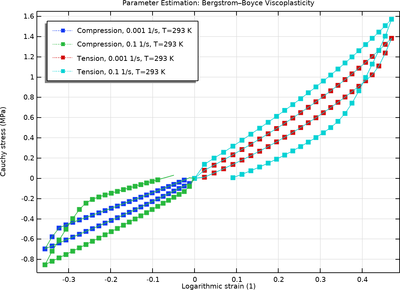

This tutorial model demonstrates how to estimate the material parameters of a viscoplastic Bergstrom–Boyce model suitable for nonequilibrium modeling of rubber-like materials. The data used for parameter estimation consists of cyclic uniaxial tension and compression tests at two ... 詳細を見る

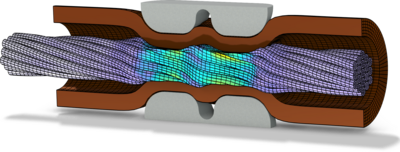

Crimping is the plastic deformation process used to form an electrical joint between a stranded conductor and a terminal. The process involves complex multi-surface contact, including self-contact, as the terminal sleeve is plastically deformed around the wire strands. This example ... 詳細を見る

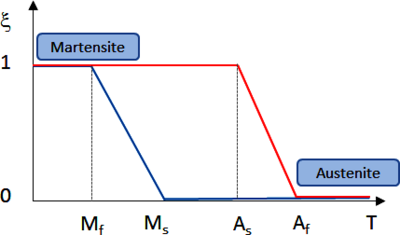

The model includes a compilation of benchmark examples included in the text book: Shape Memory Alloys: Modeling and Engineering Applications. D. Lagoudas Ed. Springer 2008. The model shows the thermomechanical properties of a NiTi alloy sample subjected to uniaxial tension-compression ... 詳細を見る

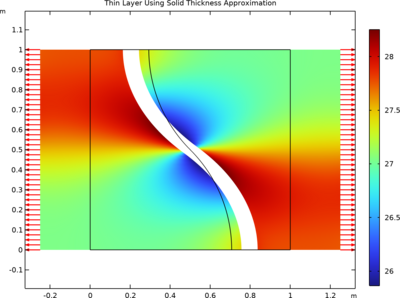

This model demonstrates alternative implementations used for describing a thin layer and the impact of the choice on the continuity of the displacement and stress fields. It is shown how a perfect interface can be obtained by asymptotically changing the material parameters. 詳細を見る

The elastoacoustic effect is a change in the speed of elastic waves that propagate in a structure undergoing static elastic deformations. The effect is used in many ultrasonic techniques for nondestructive testing of prestressed states within structures. This example studies the ... 詳細を見る

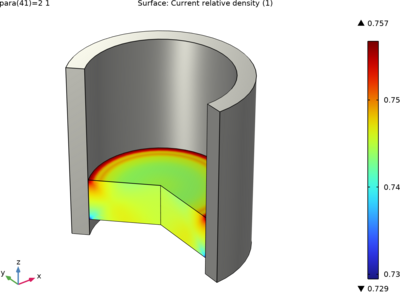

Powder compaction is a popular manufacturing process not only in powder metallurgy, but also in the pharmaceutical industry. The Capped Drucker–Prager model is commonly used for simulating the compaction processes of pharmaceutical powders, where the material properties depend on the ... 詳細を見る

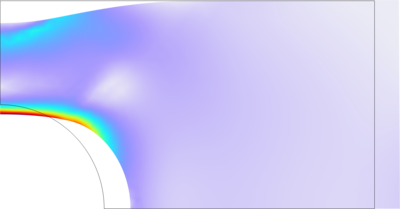

This example shows the analysis of a perforated plate loaded into the plastic regime. Part of the example is a benchmark, which you can find in section 7.10 of The Finite Element Method by O.C. Zienkiewicz. The unloading of the plate and residual stresses are also studied. In a second ... 詳細を見る

Creep is an inelastic time-dependent deformation which occurs when a material is subjected to stress at sufficiently high temperature, say 40% of the melting point or more. Experimental creep data (using constant stress and temperature) often display three different types of behavior ... 詳細を見る

Powder compaction is a key process in powder metallurgy, where it gives the flexibility to produce quality products of complex shapes for sintering. The density of the compact is a key factor to determine the overall quality of the sintered product, as regions with lower density could ... 詳細を見る