AI Copilot for Automating Simulation Setup in COMSOL Multiphysics

Simulation has become a critical part of product development, but workflows remain heavily manual and require significant expertise. Engineers often wait months on simulation requests. The delay slows design iterations and hinders early-stage feasibility assessments in the design process.

We are developing an AI-driven copilot that integrates directly with COMSOL Multiphysics to automate simulation setup, execution, and postprocessing, enabling non-experts—such as application, design, and product engineers—to run simulations using natural language. Rather than replacing COMSOL, our system wraps around it—leveraging its scripting and API capabilities to orchestrate geometry analysis, boundary condition assignment, meshing, and result extraction.

Our system comprises a planning-execution architecture that interprets the STEP geometry, understands user intent, and generates a detailed simulation plan. This plan is then executed deterministically through code generation, with full traceability and human review. At the heart of the system is a geometry-aware reasoning engine that uses graph-based representations and vision-language models (VLMs) to identify features, assign materials, apply boundary conditions, and refine the mesh.

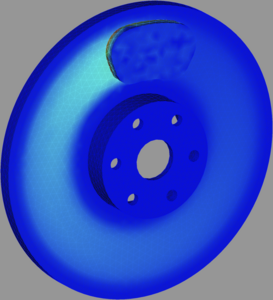

We will present an application that we are developing with a global aluminum supplier, where the copilot is used to evaluate the thermal performance of aluminum brake discs under customer-specific braking conditions. A user provides a spreadsheet of operating parameters and a STEP file of the disc and pad assembly. The copilot: • Identifies key components in the geometry • Applies the relevant material properties • Applies boundary conditions including frictional heat generation and convective cooling • Performs mesh generation and quality checks, with automatic refinement as needed • Executes a transient thermal analysis in COMSOL • Extracts outputs like maximum temperature, thermal stress, and ∆T

This application is on track to reduce simulation turnaround times from months to minutes and should empower sales and application engineers to use COMSOL in customer conversations—without manual pre-processing or CAE specialist involvement.

By using AI to help with simulation setup, our AI copilot expands access to COMSOL, reduces turnaround time, and enables faster, earlier design decisions. The technology that we’re developing generalizes to a wide range of simulation types and is extensible to support the full scope of COMSOL’s Multiphysics platform. This approach offers a path toward democratizing simulation.

ダウンロード

- Jacobian COMSOL v1.pptx - 9.26MB