研究開発におけるマルチフィジックスシミュレーションの具体例

さまざまな業界のエンジニア, 研究者, 科学者がマルチフィジックスシミュレーションを使用して革新的な製品の設計とプロセスを研究および開発しています. COMSOL カンファレンスで発表したテクニカルペーパーやプレゼンテーションからインスピレーションを得てください. 以下の選択項目を参照するか, クイック検索ツールを使用して特定のプレゼンテーションを検索するか, アプリケーション領域でフィルタリングします.

COMSOL Conference 2024 論文集を見る

Laser cutting process is usually employed in machining process, however it is also applied for dismantling nuclear facilities. Contrary to mechanical processes where tools wear out quickly and are often renewed, laser cutting process is a contactless approach, therefore there is no ... 詳細を見る

Autoliv Livbag is a company specialized in the development and manufacturing of gas generator for airbags based on pyrotechnic and compressed gas technologies. In this context, specifications of the product are very particular. Indeed, the gas generator needs to be airtight for several ... 詳細を見る

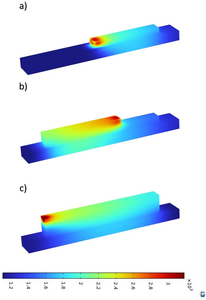

The process-induced deformation in the DED fabricated part is a critical issue to the scaling of the technology. Currently, an inefficient and expensive experiment trial-and-error approach is utilized to tackle this issue, however it is not feasible for large parts. Researchers have ... 詳細を見る

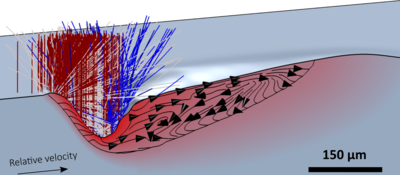

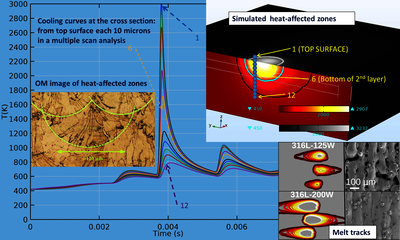

Simulation of laser processes are more and more efficient. In some cases, as welding and additive manufacturing, the physical phenomena are complex, multi-physics and multi-phases, thus some assumptions have to be done. For Laser Powder Bed Fusion, a laser beam melts and vaporizes the ... 詳細を見る

A numerical model of laser welding process applied on highly optically reflective and thermally conductive materials such as copper has been developped. The latter considers multiphysical couplings of CFD, heat transfers and phase-field representation to account for topological ... 詳細を見る

In this paper, we present a study of the simulation of Directed Energy Deposition (DED) Additive Manufacturing (AM) using a multiphysics approach. We use a combination of Heat Transfer in Fluids, Solid Mechanics and Laminar Flow physics to accurately simulate the DED process. The ... 詳細を見る

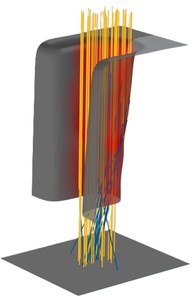

The present work introduces a new methodology, based on COMSOL Multiphysics® Application Builder, to account for the “beam trapping” effect in multiphysical modelling of laser welding. Incident intensities involved in laser welding processes are high enough to induce material ... 詳細を見る

An auto-consistent multiphysical 3D model with strong coupling between Heat Transfer, Navier Stokes and ALE problems is proposed for the description of transient development of the keyhole and the melted zone in laser welding of metallic materials. It showed a satisfactory correspondence ... 詳細を見る

Laser cladding is an additive manufacturing process, where a laser beam creates a melt pool, into which powder is fed from a powder nozzle. Due to the feed motion of the laser beam and the powder nozzle relative to the workpiece, coatings and 3D parts can be deposited, which consist of ... 詳細を見る

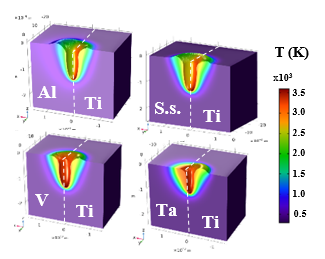

Selective Laser Melting (SLM), like many other additive manufacturing techniques, offers flexibility in design expected to become a disruption to the manufacturing industry. The current cost of SLM process does not favor a try-and-error way of research; which gives more room for ... 詳細を見る