アプリケーションギャラリには電気, 構造, 音響, 流体, 熱および化学分野に関連する COMSOL Multiphysics® チュートリアルおよびデモアプリファイルが用意されています. これらの例はチュートリアルモデルまたはデモアプリファイルとそれに付随する手順をダウンロードすることにより独自のシミュレーション作業の開始点として使用できます.

クイック検索機能を使用して専門分野に関連するチュートリアルやアプリを検索します. MPHファイルをダウンロードするには, ログインするか, 有効な COMSOL ライセンスに関連付けられている COMSOL Access アカウントを作成します. ここで取り上げた例の多くは COMSOL Multiphysics® ソフトウェアに組み込まれ ファイルメニューから利用できるアプリケーションライブラリからもアクセスできることに注意してください.

The powder compaction process is becoming common in the manufacturing industry, thanks to its potential to produce components of complex shape and high strength. In this example, the compaction of iron powder to form an axisymmetric rotational flanged component is analyzed with capped ... 詳細を見る

This tutorial model demonstrates how to set up a parameter estimation study for fitting the material parameters of an Ogden hyperelastic model to experimental data. The procedure considers multiple load cases under large deformations, which is often necessary to obtain constitutive ... 詳細を見る

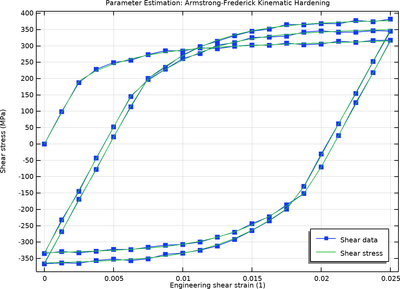

This tutorial model demonstrates how to estimate the material parameters of a combined hardening elastoplastic material model given cyclic shear data. 詳細を見る

This version of the balloon inflation example demonstrates how the Shell and Membrane interfaces can be used to model thin structures made of hyperelastic materials. The example is identical to the Model Library model 'Inflation of a spherical rubber balloon', except that the Membrane ... 詳細を見る

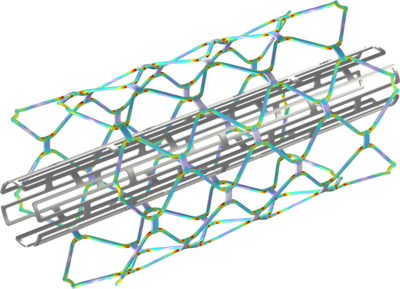

A stent is a wire-mesh tube used to open a coronary artery during angioplasty, a process for the removal or compression of plaque. Their design is of significance for percutaneous transluminal angioplasty with stenting. During this procedure, a stent is deployed into the blood vessel by ... 詳細を見る

Stents are used in biomedical applications to support the inner wall of veins and arteries. Self-expanding stents made of shape memory alloys work differently from balloon-inflated stents, as these stents are crimped to the artery diameter at low temperature then released while the blood ... 詳細を見る

This example shows how to compute deformations caused by secondary creep in a turbine stator blade. The creep rate is highly influenced by temperature, and the deformation and stress relaxation is thus controlled by the temperature field. 詳細を見る

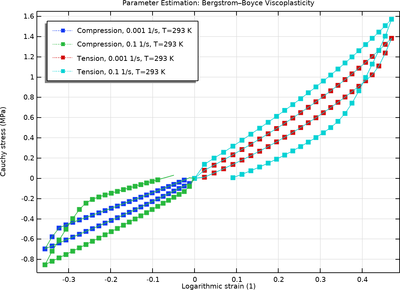

This tutorial model demonstrates how to estimate the material parameters of a viscoplastic Bergstrom–Boyce model suitable for nonequilibrium modeling of rubber-like materials. The data used for parameter estimation consists of cyclic uniaxial tension and compression tests at two ... 詳細を見る

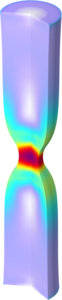

A circular metal bar is subjected to uniaxial tension. As an effect, large plastic strains develop. The material is elastoplastic with nonlinear isotropic hardening. As the elongation is increased, the decrease in radius becomes strongly nonuniform, so called "necking". The development ... 詳細を見る

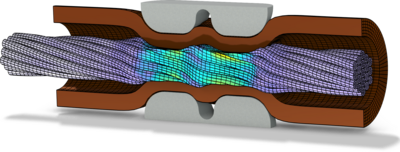

Crimping is the plastic deformation process used to form an electrical joint between a stranded conductor and a terminal. The process involves complex multi-surface contact, including self-contact, as the terminal sleeve is plastically deformed around the wire strands. This example ... 詳細を見る