アプリケーションギャラリには電気, 構造, 音響, 流体, 熱および化学分野に関連する COMSOL Multiphysics® チュートリアルおよびデモアプリファイルが用意されています. これらの例はチュートリアルモデルまたはデモアプリファイルとそれに付随する手順をダウンロードすることにより独自のシミュレーション作業の開始点として使用できます.

クイック検索機能を使用して専門分野に関連するチュートリアルやアプリを検索します. MPHファイルをダウンロードするには, ログインするか, 有効な COMSOL ライセンスに関連付けられている COMSOL アクセスアカウントを作成します. ここで取り上げた例の多くは COMSOL Multiphysics® ソフトウェアに組み込まれ ファイルメニューから利用できるアプリケーションライブラリからもアクセスできることに注意してください.

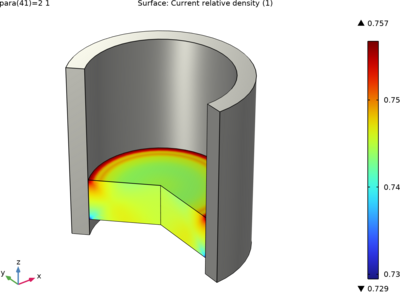

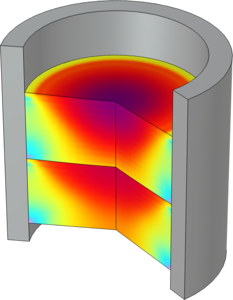

The powder compaction process is becoming common in the manufacturing industry, thanks to its potential to produce components of complex shape and high strength. In this example, the compaction of iron powder to form an axisymmetric rotational flanged component is analyzed with capped ... 詳細を見る

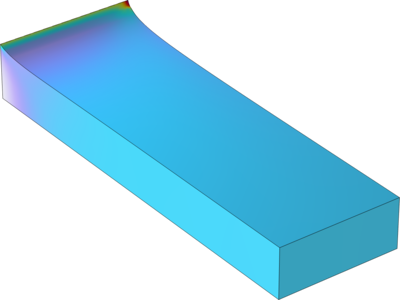

This model showcases how to use fibers in thin layers to model thin anisotropic composites embedded in a solid without explicitly drawing either the layer of material or the reinforcing fibers. Here, it is used to model steel cords in tire belts that are used to provide structural ... 詳細を見る

This model demonstrates how to set up a phase field damage multiphysics model to predict crack propagation in thermoelastic solids under large deformations. The crack-driving force depends on the principal stresses, which in turn depend on the temperature distribution in the solid ... 詳細を見る

The process of filling a water balloon is a vivid example for the interaction of fluid pressure and a nonlinear structural material. This model demonstrates how straightforward a FSI simulation model is set up in COMSOL. 詳細を見る

Powder compaction is a popular manufacturing process not only in powder metallurgy, but also in the pharmaceutical industry. The Capped Drucker–Prager model is commonly used for simulating the compaction processes of pharmaceutical powders, where the material properties depend on the ... 詳細を見る

This tutorial model demonstrates how to set up a parameter estimation study for fitting the material parameters of an Ogden hyperelastic model to experimental data. The procedure considers multiple load cases under large deformations, which is often necessary to obtain constitutive ... 詳細を見る

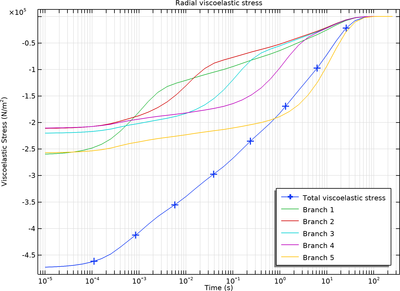

Anisotropic hyperelastic materials are used for modeling collagenous soft tissue in arterial walls. The Arterial Wall Mechanics application describes a section of an artery based on the Holzapfel–Gasser-Ogden hyperelastic material model. In this example the dynamic behavior of the artery ... 詳細を見る

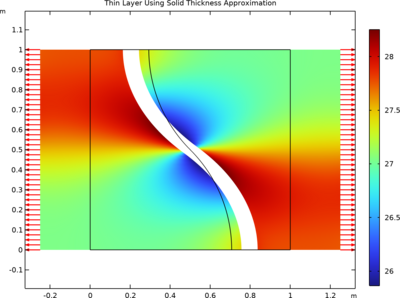

This model demonstrates alternative implementations used for describing a thin layer and the impact of the choice on the continuity of the displacement and stress fields. It is shown how a perfect interface can be obtained by asymptotically changing the material parameters. 詳細を見る

This model shows how you can implement a user defined hyperelastic material, using the strain density energy function. The model used is a general Mooney–Rivlin hyperelastic material model defined by a polynomial. In this example, you will see two material models based on the defined ... 詳細を見る

Powder compaction is a key process in powder metallurgy, where it gives the flexibility to produce quality products of complex shapes for sintering. The density of the compact is a key factor to determine the overall quality of the sintered product, as regions with lower density could ... 詳細を見る