Electrochemical Machining of a Microbore

Application ID: 13267

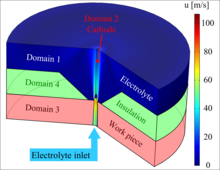

For several high-precision applications, especially in hydraulic systems and fuel injectors, micro bores are needed. In most cases the shape of the injection hole, especially the edge rounding, has a significant influence on the atomization of fluids and therefore on the combustion process. Usually these micro bores are machined by electrical discharge machining (EDM). Due to the process characteristics of EDM sharp edges arise and a specific influence on the edge shape is not possible. For this reason a specific adjustment of the edge rounding is required. Therefore an Electrochemical Machining (ECM) process has been developed and investigated by help of COMSOL Multiphysics.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

- COMSOL Multiphysics® and

- either the バッテリデザインモジュール, 腐食解析モジュール, or 電気めっきモジュール

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the 製品仕様一覧 and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.