Energy-Based Thermal Fatigue Prediction in a Ball Grid Array

Application ID: 16143

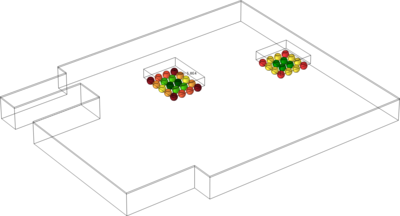

In a cooling system, a microelectronic component has been identified as the critical link. Since the power is repeatedly switched on and off, the component is subjected to thermal cycling. As a results a crack grows through a solder joint and disconnects the chip from the printed circuit board so that the component loses its operational functionality. The lifetime of the solder joints in two ball grid assemblies is predicted based on the Darveaux energy-based model. The fatigue model evaluates damage based on an averaged energy dissipation density in a thin layer where a crack will grow.

This example is based on a model from the Nonlinear Structural Materials Module, Viscoplastic Creep in Solder Joints. Since the model contains several solder joints that are modeled with a viscoplastic material, many degrees of freedom are required in order to simulate the correct creep behavior in all elements. From the fatigue point of view, only the critical part of the model is of interest. In order to capture it, the concept of submodeling is used. This technique requires two steps. In the first one, the full model is analyzed with a coarse mesh in order to simulate the general trends and to identify the critical solder ball. In the second step a submodel with a fine mesh containing the critical part is made and the study is recomputed. The global effects from the full model are transferred to the submodel via appropriate boundary conditions.

この model の例は, 通常次の製品を使用して構築されるこのタイプのアプリケーションを示しています.

ただし, これを完全に定義およびモデル化するには, 追加の製品が必要になる場合があります. さらに, この例は, 次の製品の組み合わせのコンポーネントを使用して定義およびモデル化することもできます.

- COMSOL Multiphysics® and

- 疲労解析モジュール and

- 非線形構造材料モジュール and

- 構造力学モジュール

アプリケーションのモデリングに必要な COMSOL® 製品の組み合わせは, 境界条件, 材料特性, フィジックスインターフェース, パーツライブラリなど, いくつかの要因によって異なります. 特定の機能が複数の製品に共通している場合もあります. お客様のモデリングニーズに適した製品の組み合わせを決定するために, 製品仕様一覧 を確認し, 無償のトライアルライセンスをご利用ください. COMSOL セールスおよびサポートチームでは, この件に関するご質問にお答えしています.