Continuous Casting — Apparent Heat Capacity Method

Application ID: 382

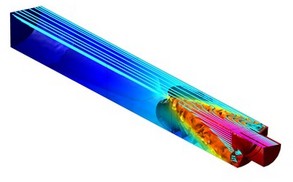

This example models the casting process of a metal rod from liquid to solid state using the Non-Isothermal Flow multiphysics interface, which combines heat transfer and fluid flow. The model describes the fluid and solid flow and heat transport, including the phase transfer from melt to solid. This phase change causes momentum changes, latent heat release and a variation in physical properties.

The results of the model allows for optimization of the process in terms of casting rate and cooling. The model also allows the influence of the die shape on the flow field of the melted metal.

この model の例は, 通常次の製品を使用して構築されるこのタイプのアプリケーションを示しています.

ただし, これを完全に定義およびモデル化するには, 追加の製品が必要になる場合があります. さらに, この例は, 次の製品の組み合わせのコンポーネントを使用して定義およびモデル化することもできます.

- COMSOL Multiphysics® and

- either the 伝熱モジュール, 多孔質媒体流れモジュール, or 地下水流モジュール and

- either the CFD モジュール, 化学反応工学モジュール, 伝熱モジュール, プラズマモジュール, or 多孔質媒体流れモジュール

アプリケーションのモデリングに必要な COMSOL® 製品の組み合わせは, 境界条件, 材料特性, フィジックスインターフェース, パーツライブラリなど, いくつかの要因によって異なります. 特定の機能が複数の製品に共通している場合もあります. お客様のモデリングニーズに適した製品の組み合わせを決定するために, 製品仕様一覧 を確認し, 無償のトライアルライセンスをご利用ください. COMSOL セールスおよびサポートチームでは, この件に関するご質問にお答えしています.