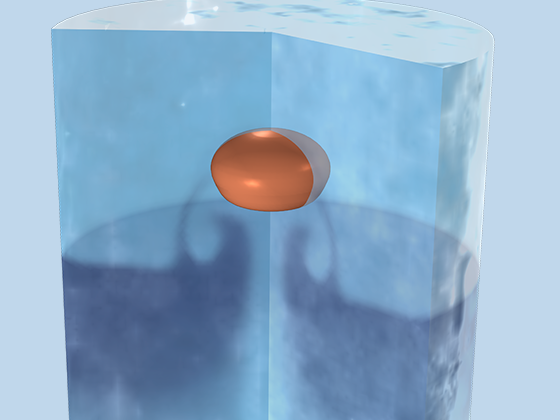

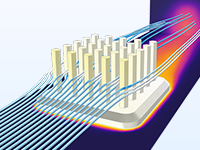

層流およびクリープ流れ

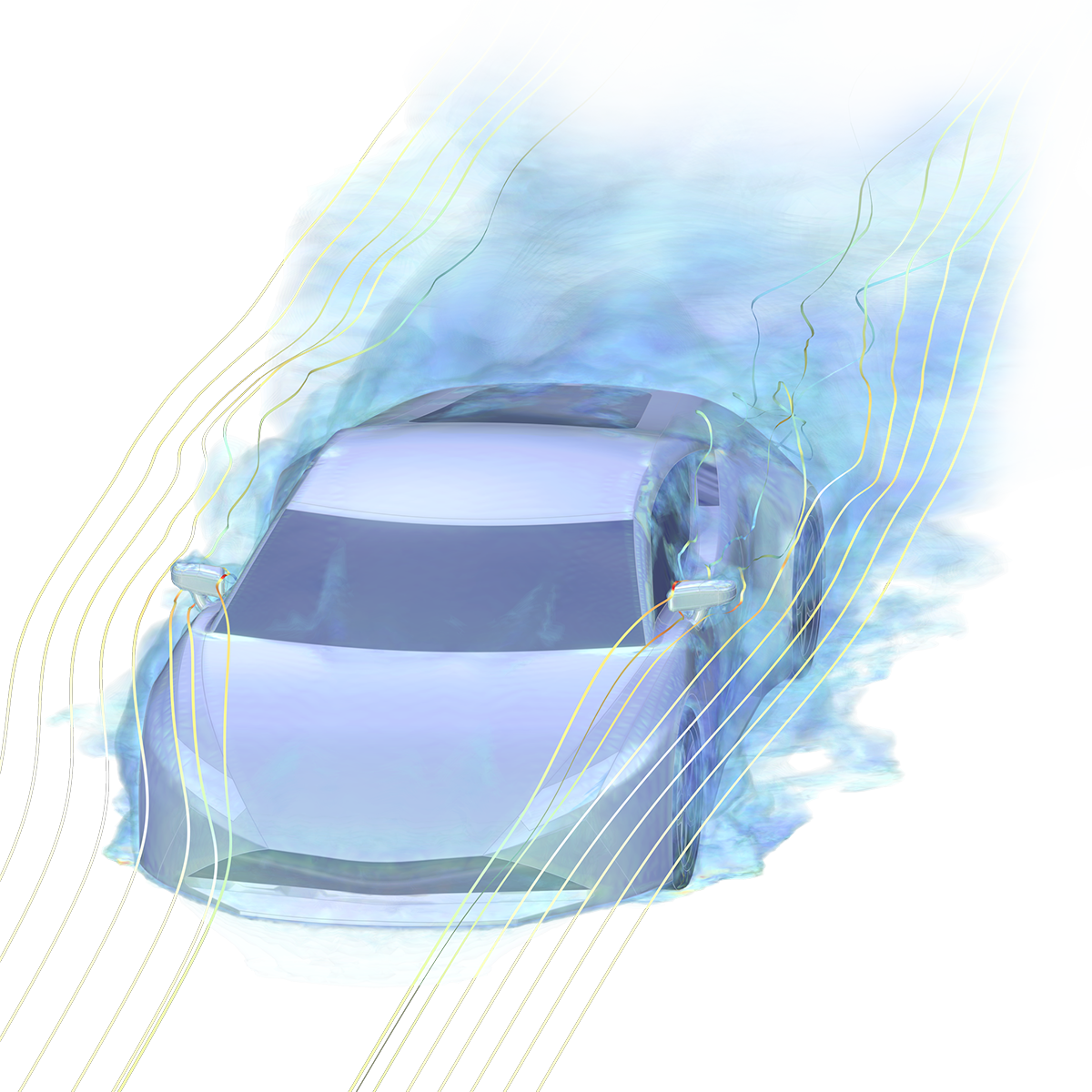

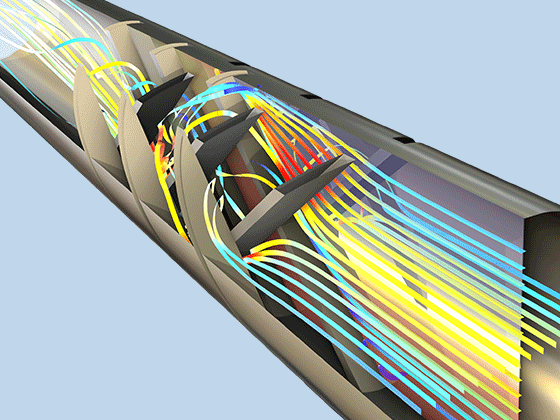

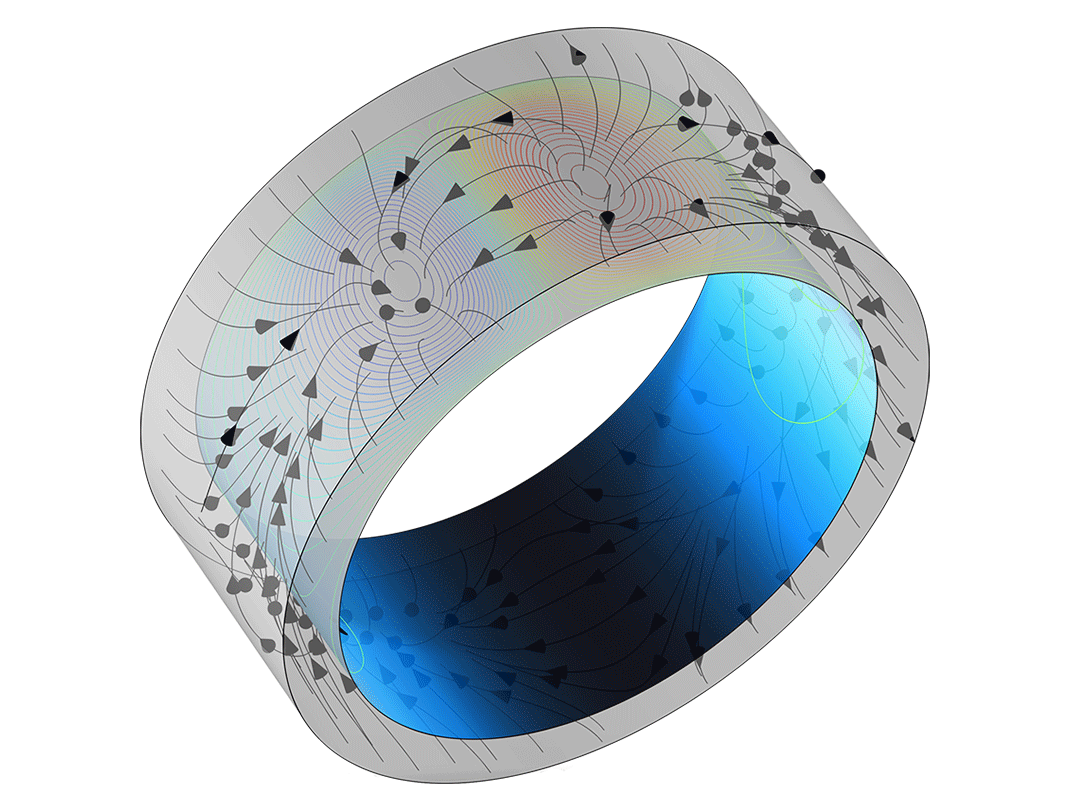

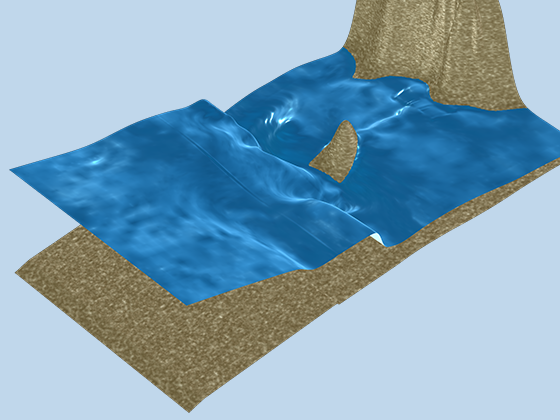

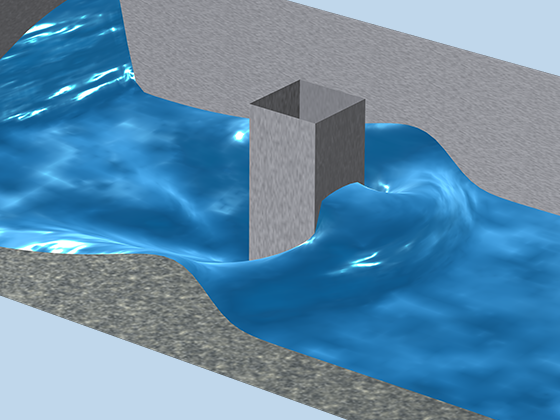

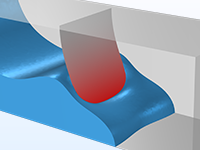

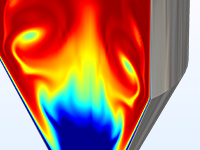

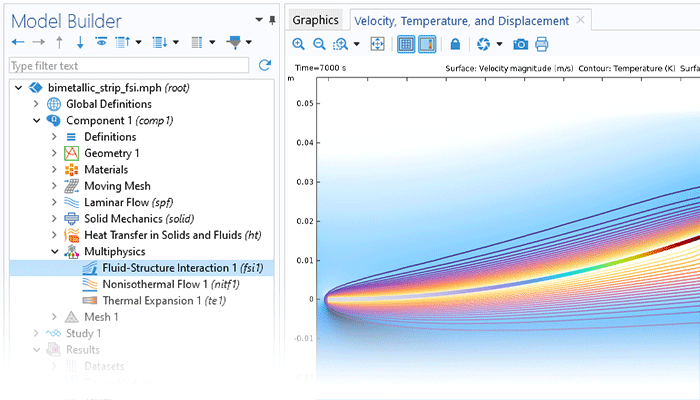

ナビエ・ストークス方程式を使用して過渡流や定常流をモデル化するか, ストークス方程式でクリープ流れをモデル化します.

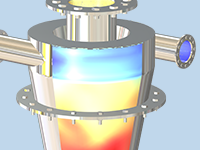

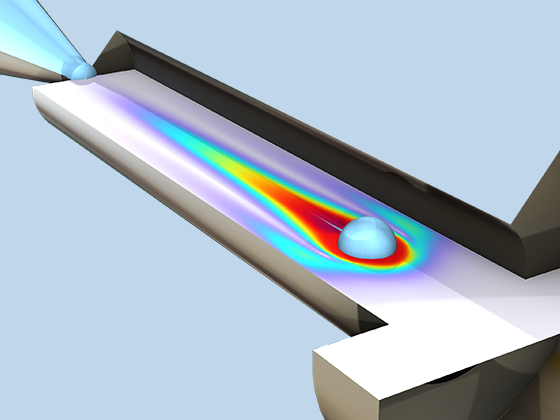

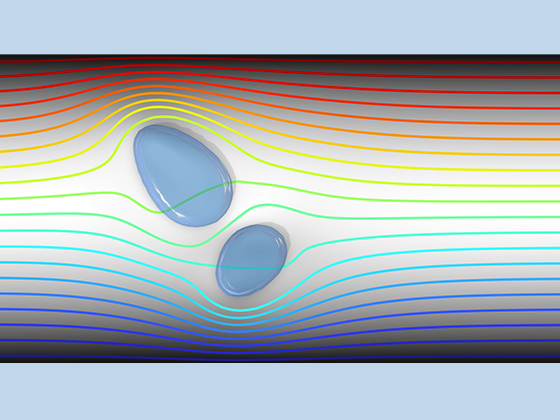

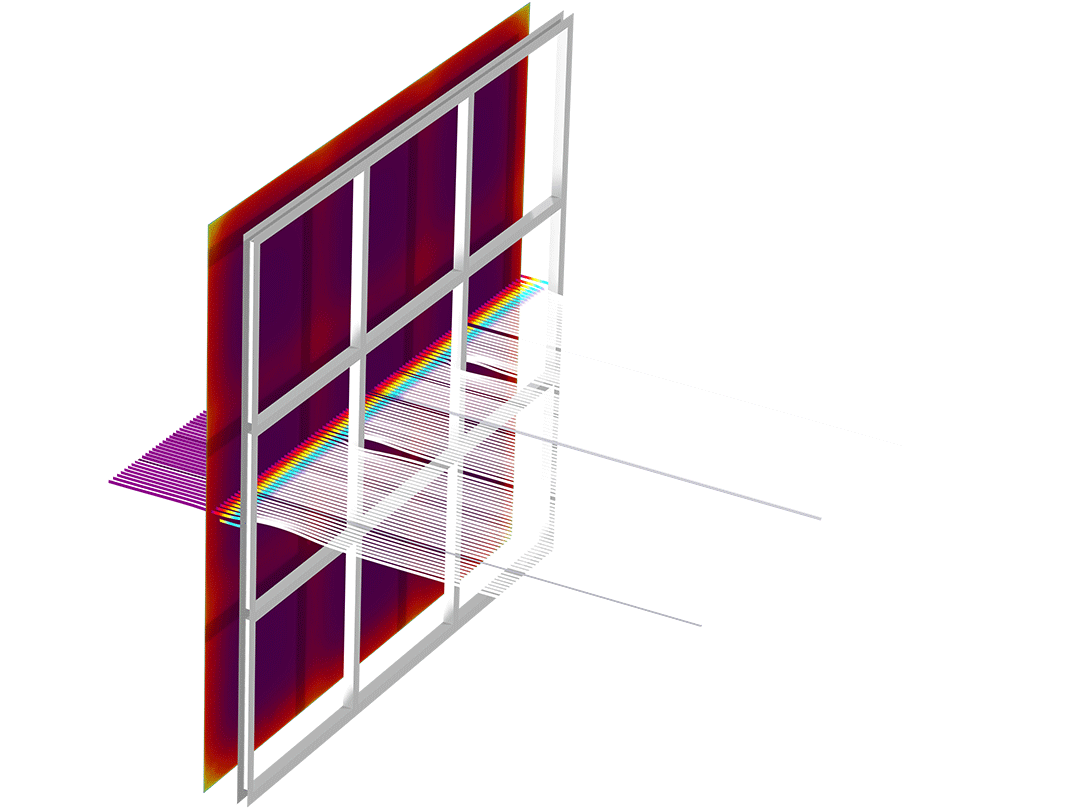

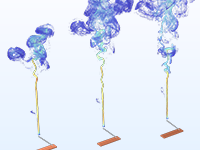

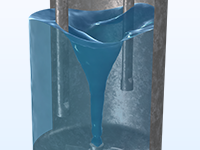

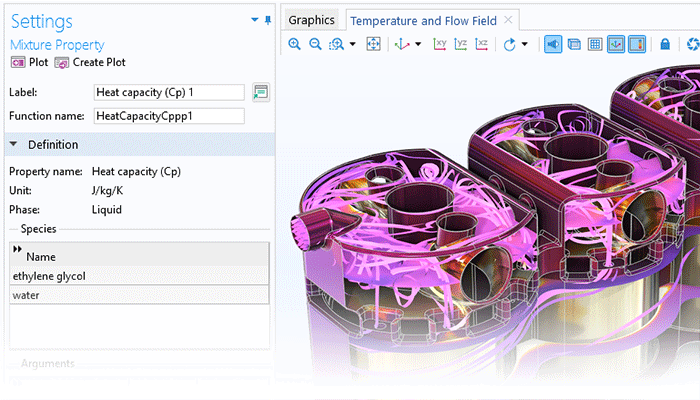

一定の密度と粘度を持つ流体をモデル化するだけでなく, モジュールは, 粘度と密度が温度, 局所組成, 電場, またはその他のモデル化された場または変数に依存する流体の研究をサポートします. 一般に, 密度, 粘度, および運動量ソースは, 従属変数の任意の関数, および従属変数の導関数にすることができます.

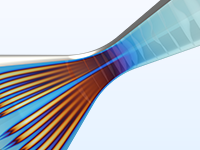

非ニュートン流体の場合, モデルを簡単に設定できるように, べき乗則, Carreau, Bingham, Herschel–Bulkley, Casson などの粘度用の定義済みの汎用レオロジモデルがあります.

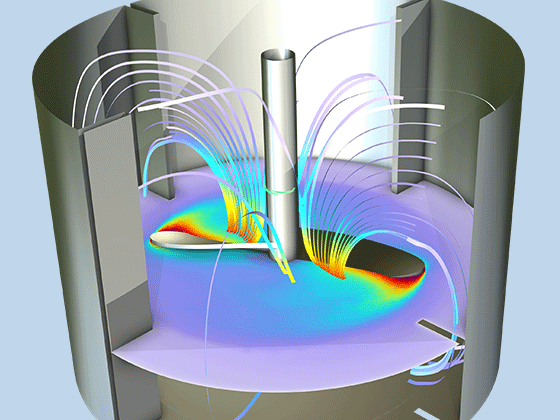

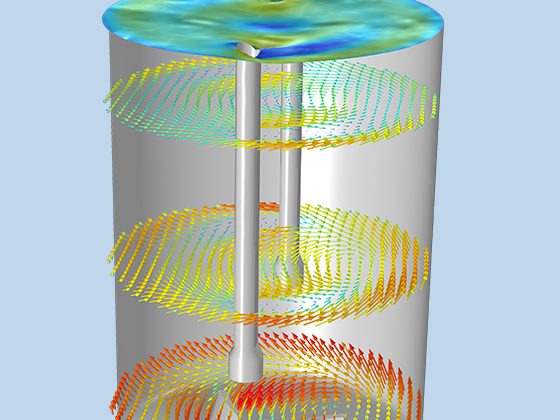

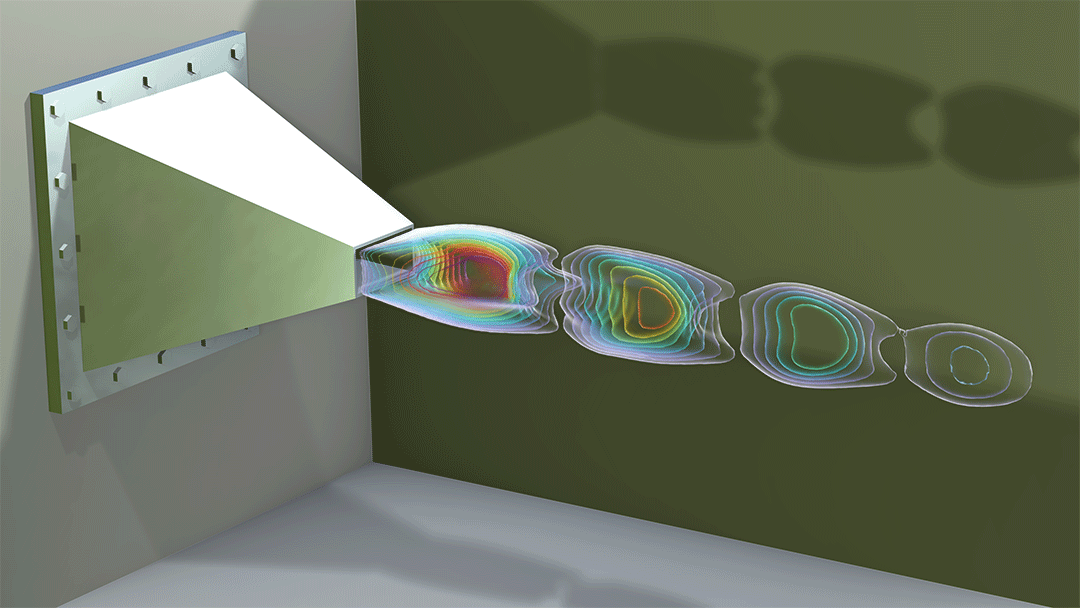

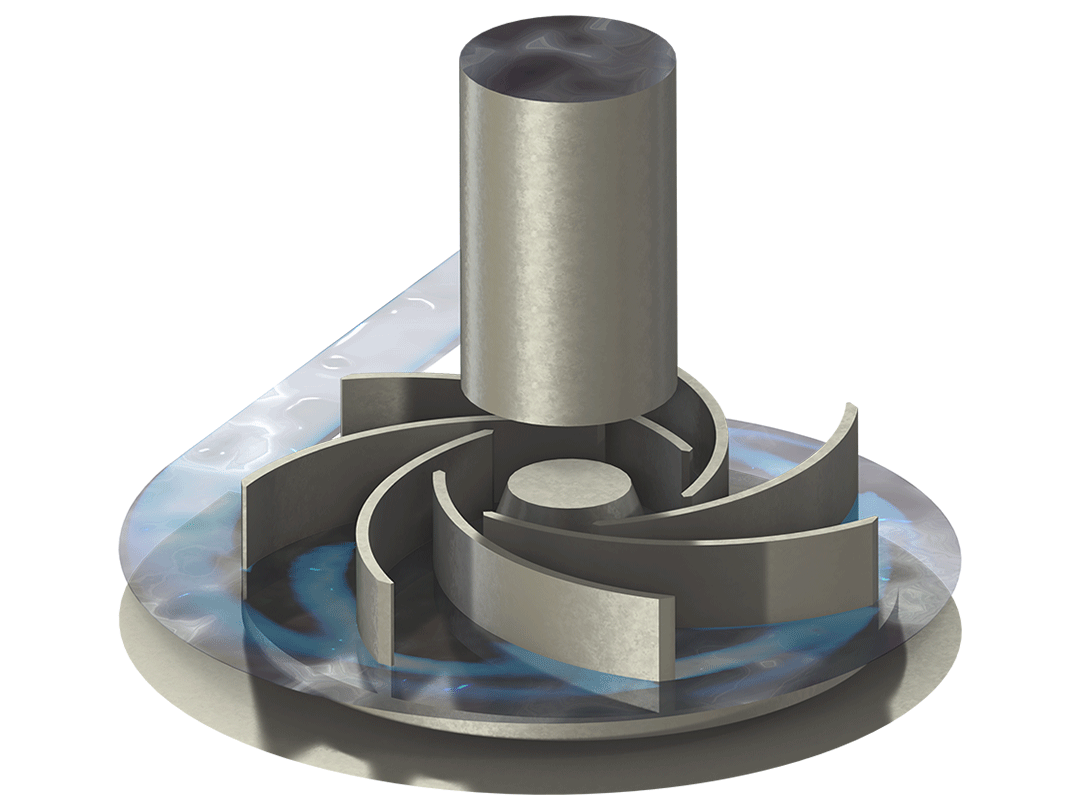

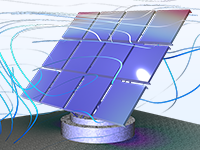

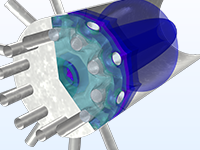

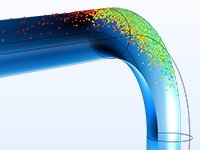

また, バルブの開閉やインペラーの回転など, 移動構造内の層流をモデル化する機能もあります.