マルチフィジックスモデリングのための非線形構造材料

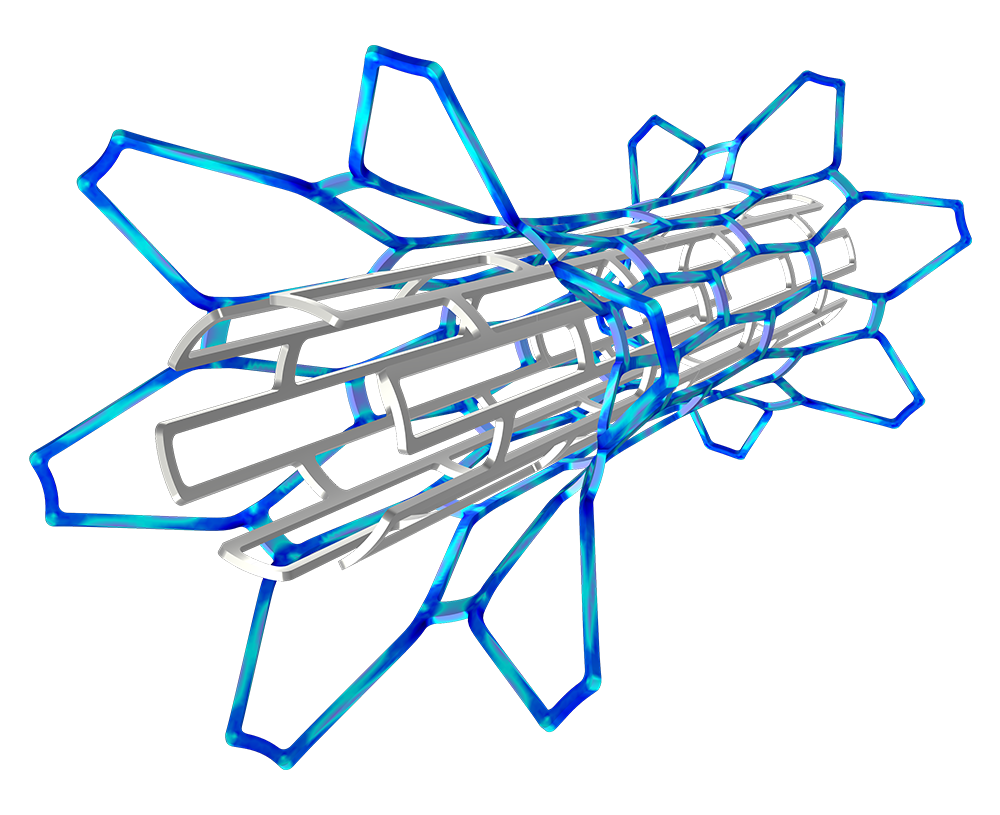

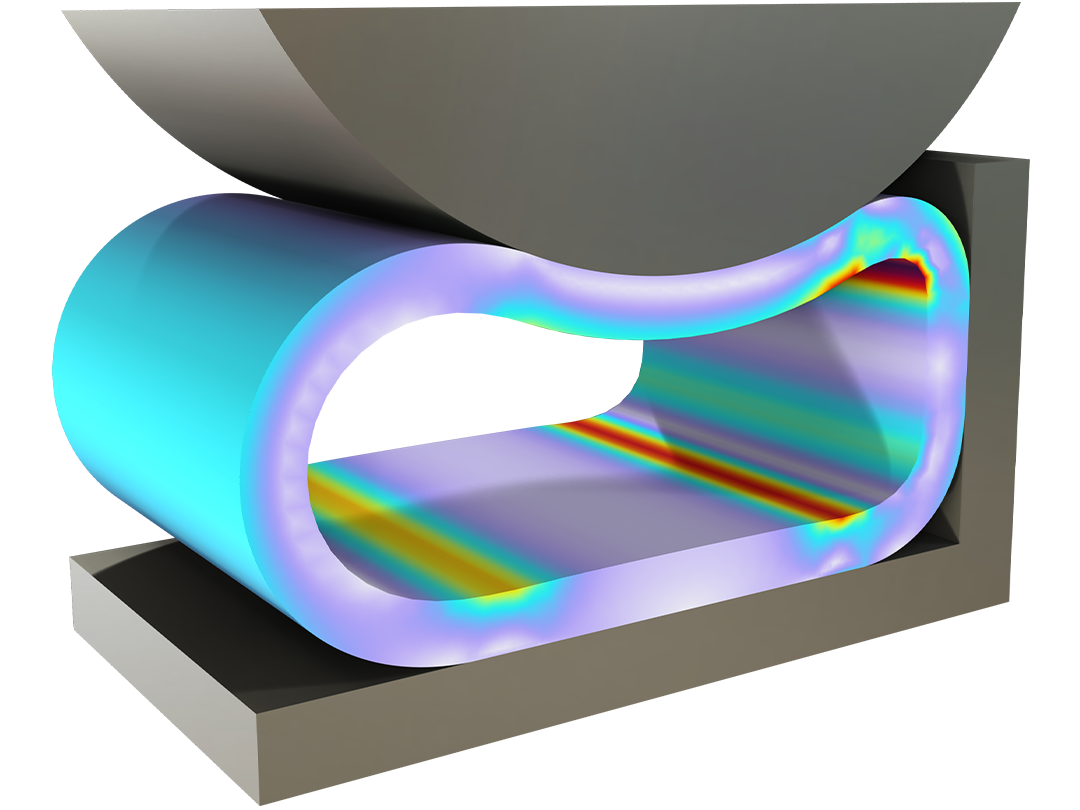

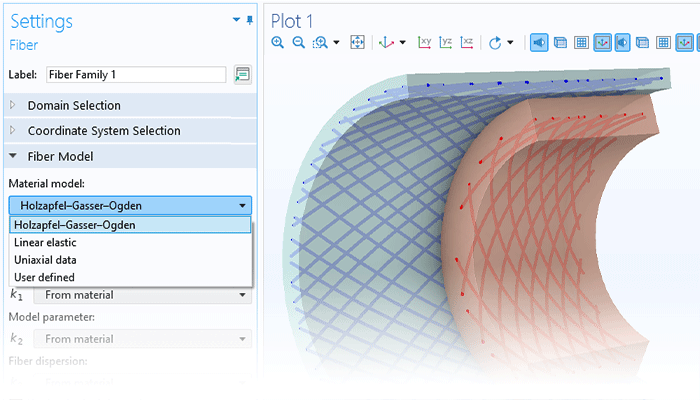

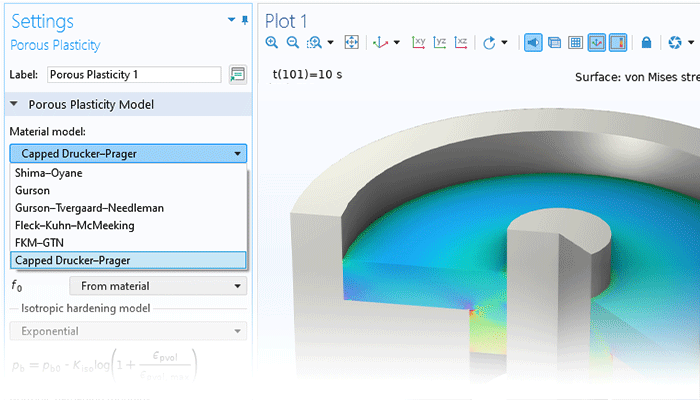

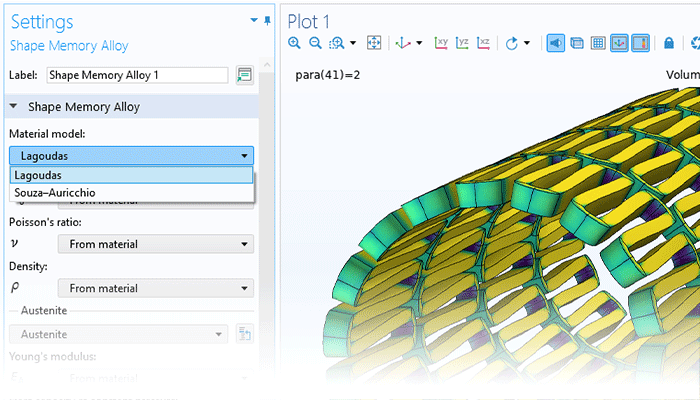

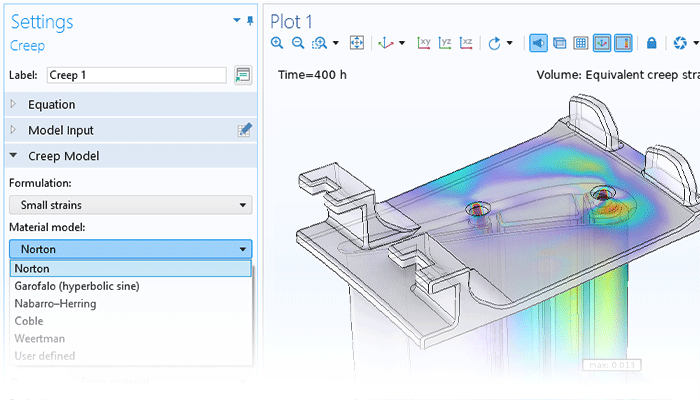

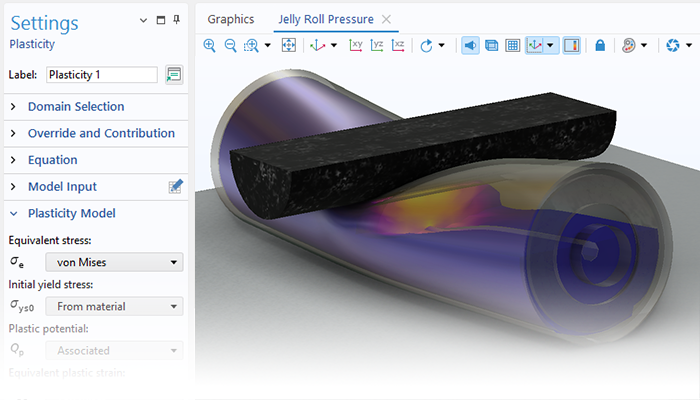

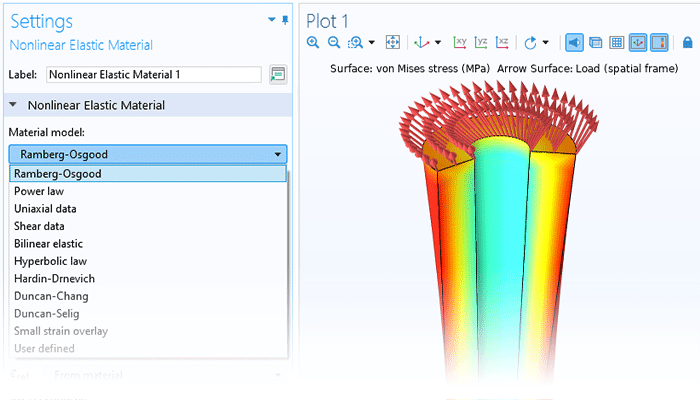

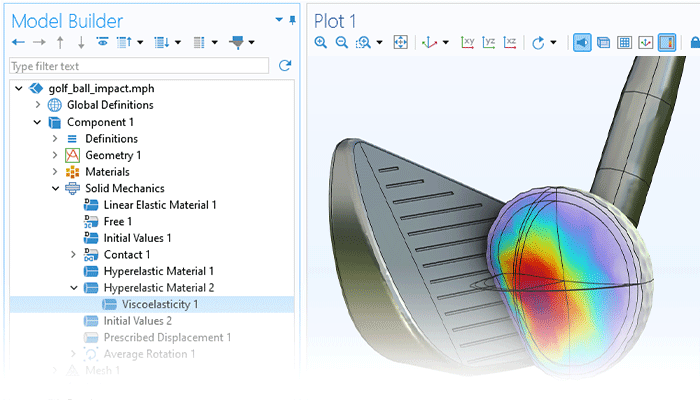

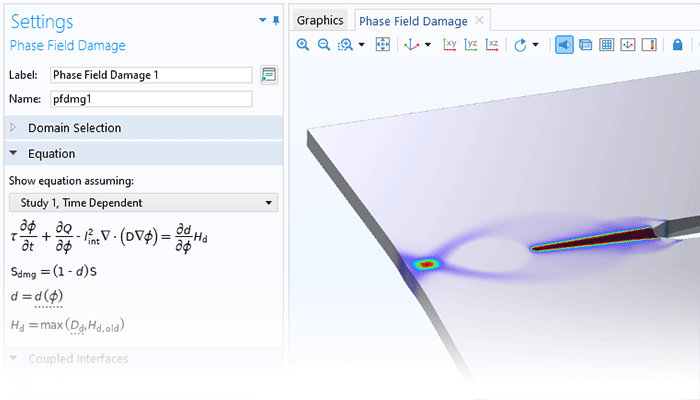

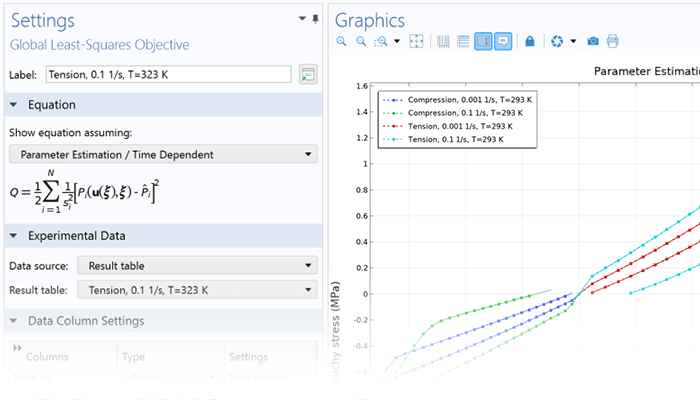

非線形材料モデリング機能は, 構造力学モジュールまたは MEMS モジュールで利用可能なすべての構造解析を拡張します. 線形弾性, 超弾性, または非線形弾性材料モデルは, 塑性, クリープ, 粘塑性, 損傷などの非線形効果と組み合わせることができ, COMSOL Multiphysics® シミュレーションソフトウェアの汎用性により, 数回のクリックでマルチフィジックス連成を容易に組み込むことができます. ユーザーは, 例えば応力やひずみの不変量に基づいて独自のモデルを定義し, 超弾性に対する独自の流動則, クリープ則, ひずみエネルギー密度関数を作成できます.

COMSOL Multiphysics® ソフトウェアプラットフォームには, 熱膨張, 間隙水圧, 流体構造相互作用など, その他多くのマルチフィジックス現象をモデリングするためのマルチフィジックス機能が組み込まれています. 非線形構造材料モジュールに含まれるすべての構造材料は, マルチフィジックス解析で使用できます.