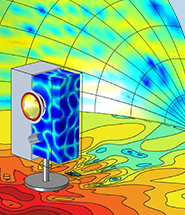

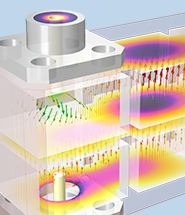

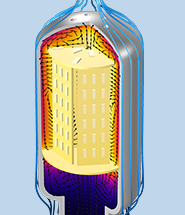

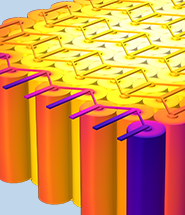

マルチフィジックスモデリングによる正確な結果

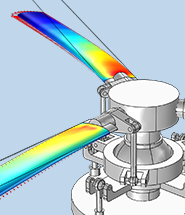

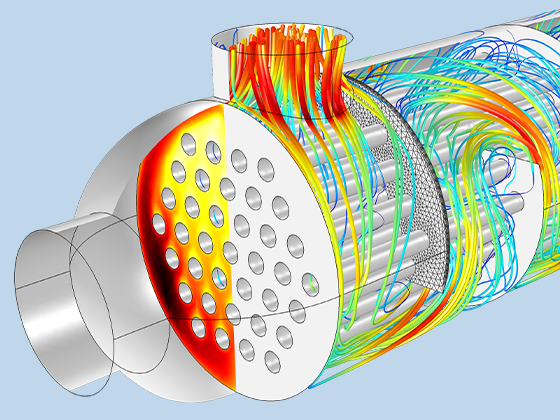

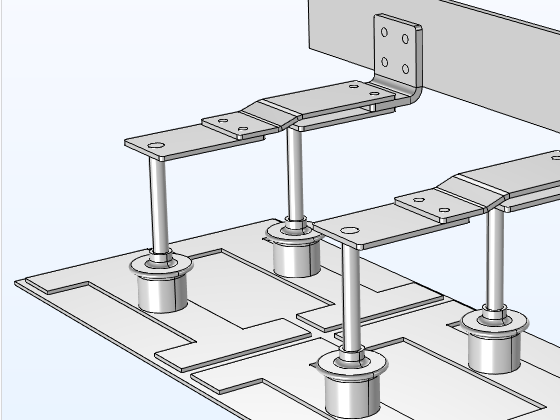

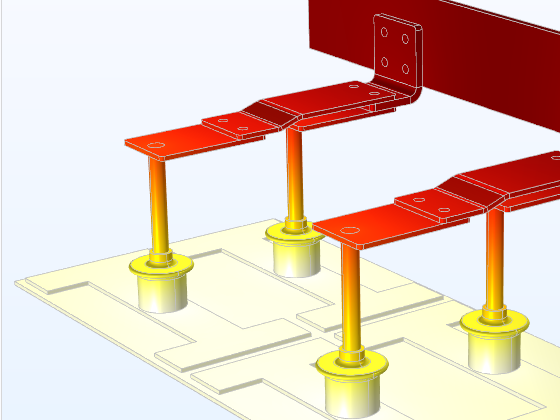

モデリングは, 実験と併用することで, プロセスやデバイスの最適化をより早く行うことができ, 多くの場合, 実験やプロトタイプのテストを単独で行うよりも, 効率的かつ正確に行うことができます. 実験的に検証されたモデルを構築して解析を行うことは, 実験室で行う研究よりも利便性が高く, デザインやプロセスをより深く理解することができます.

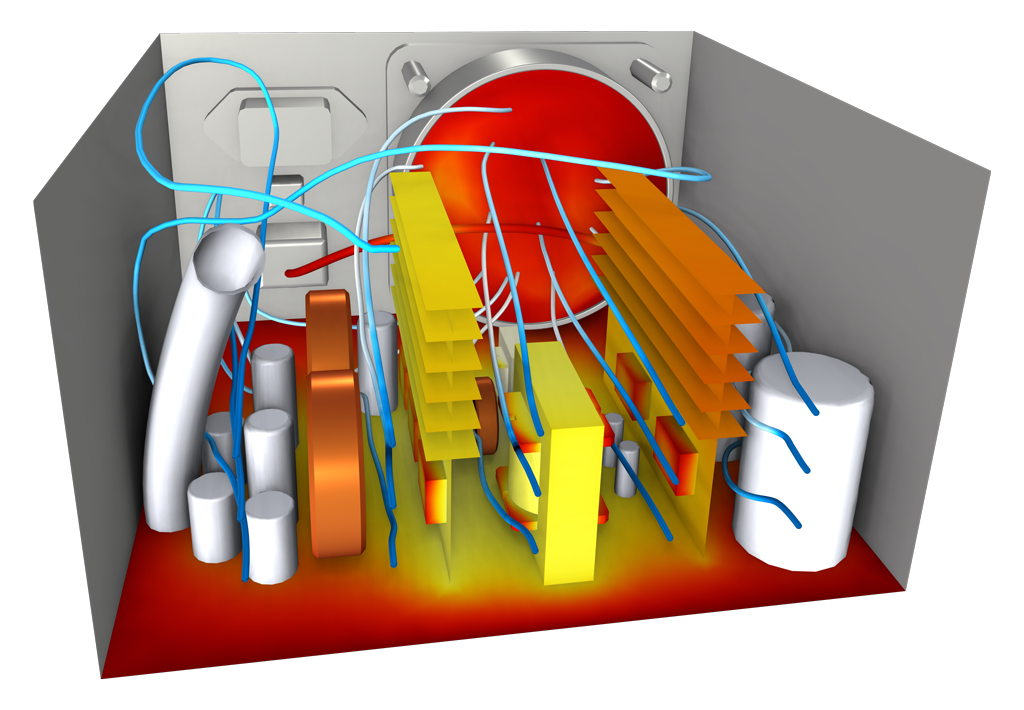

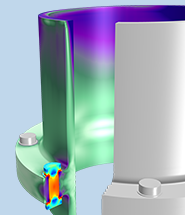

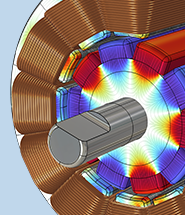

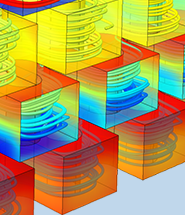

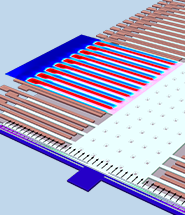

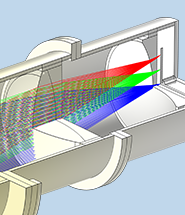

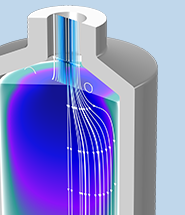

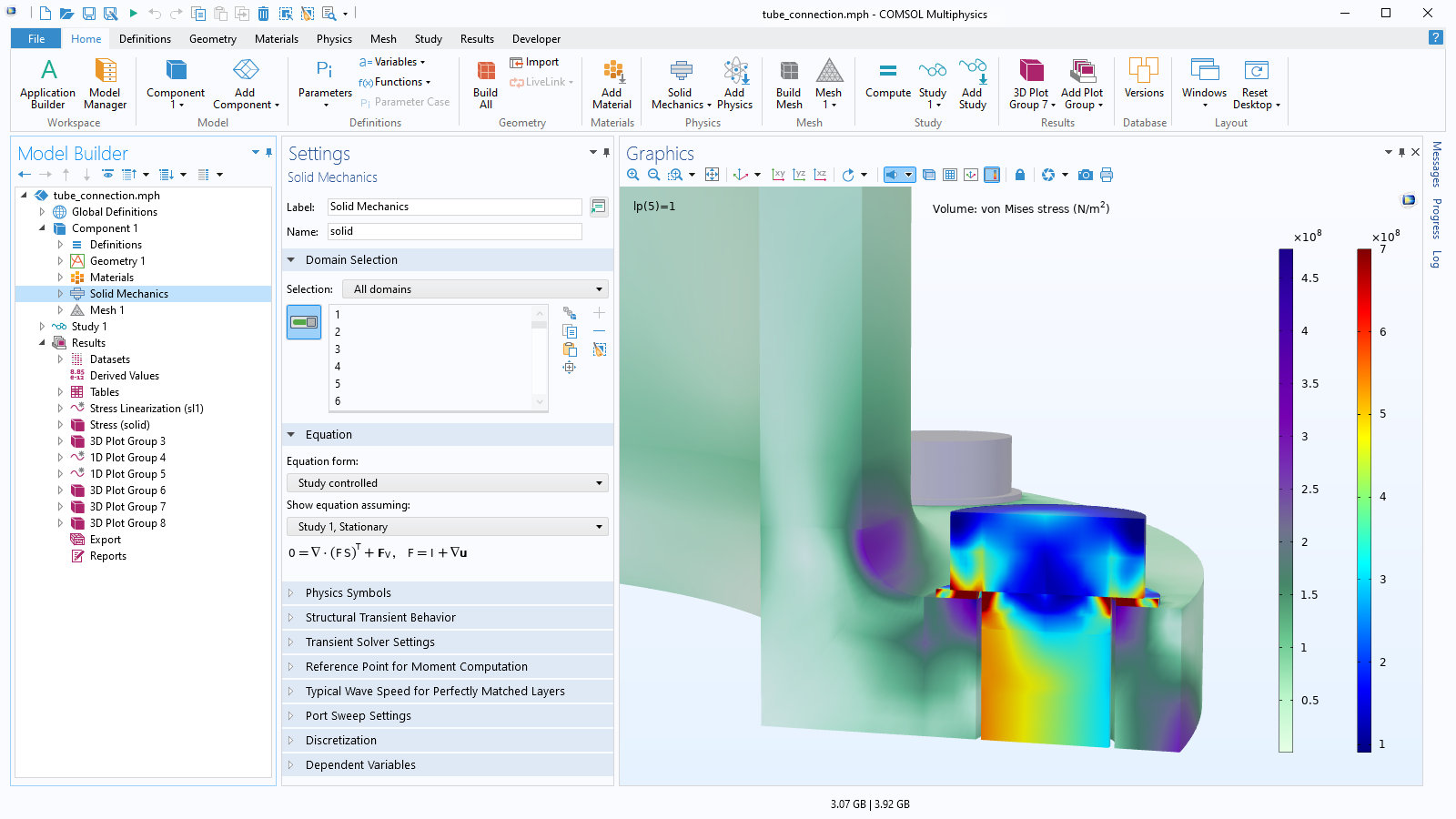

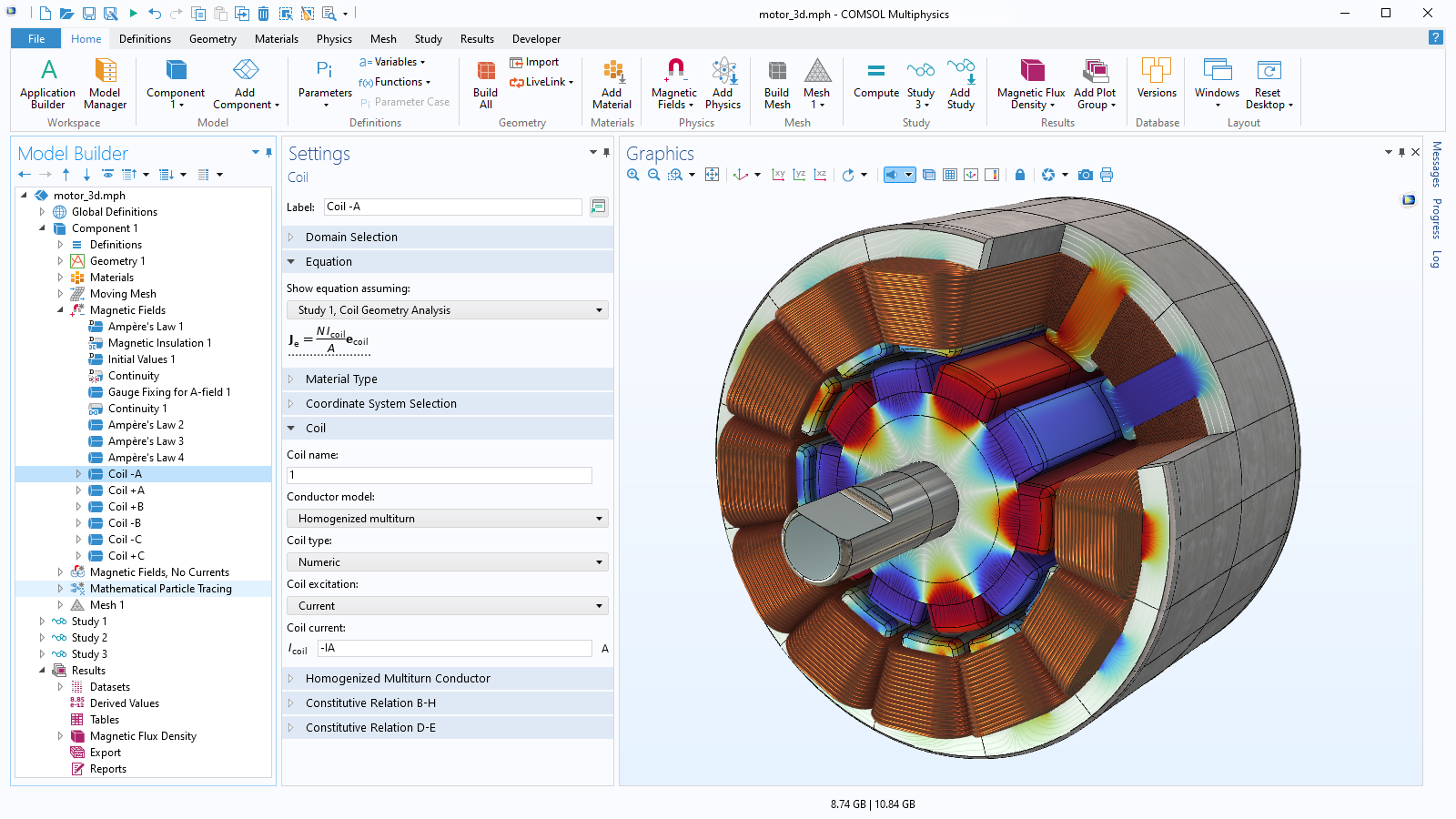

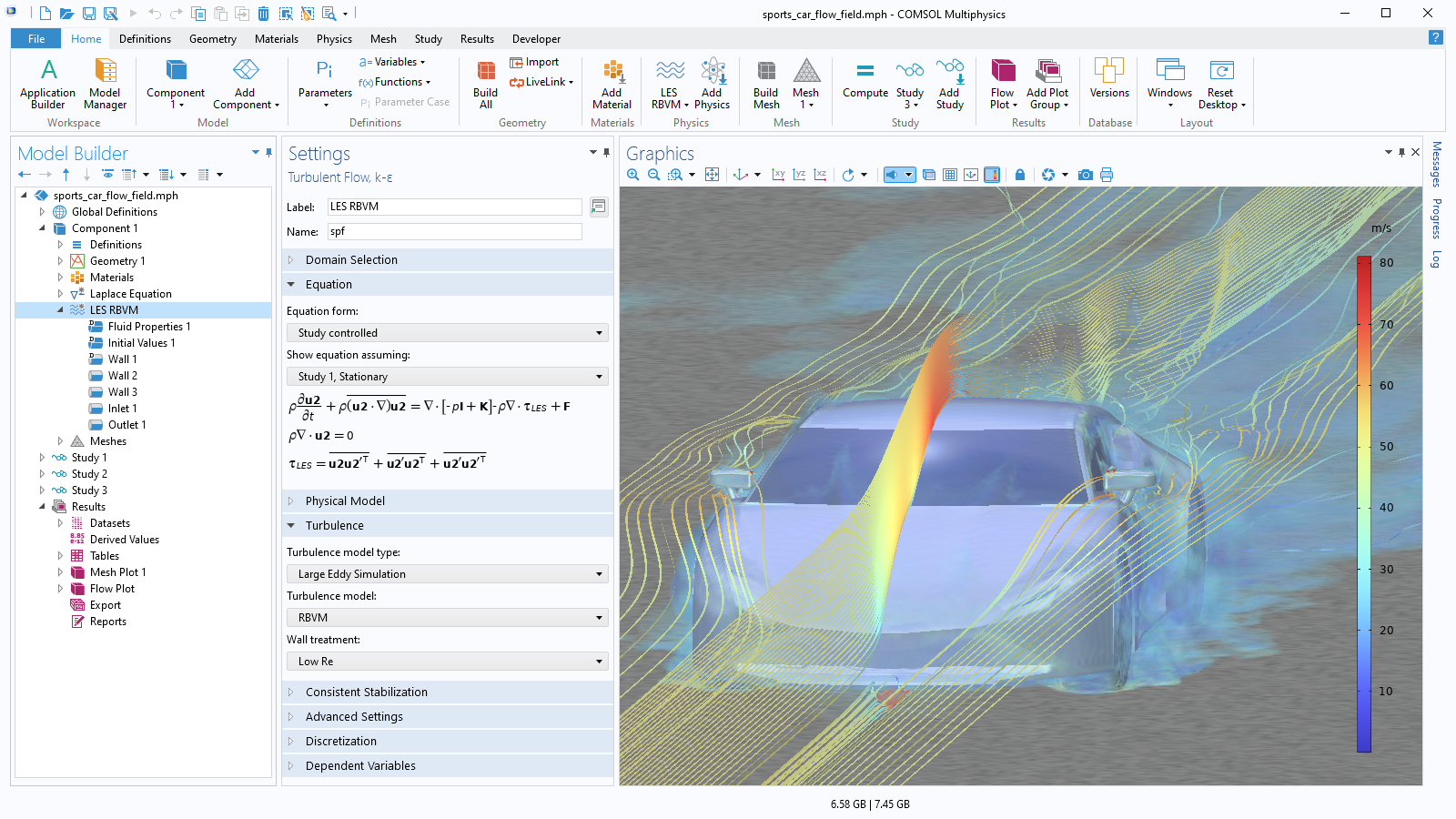

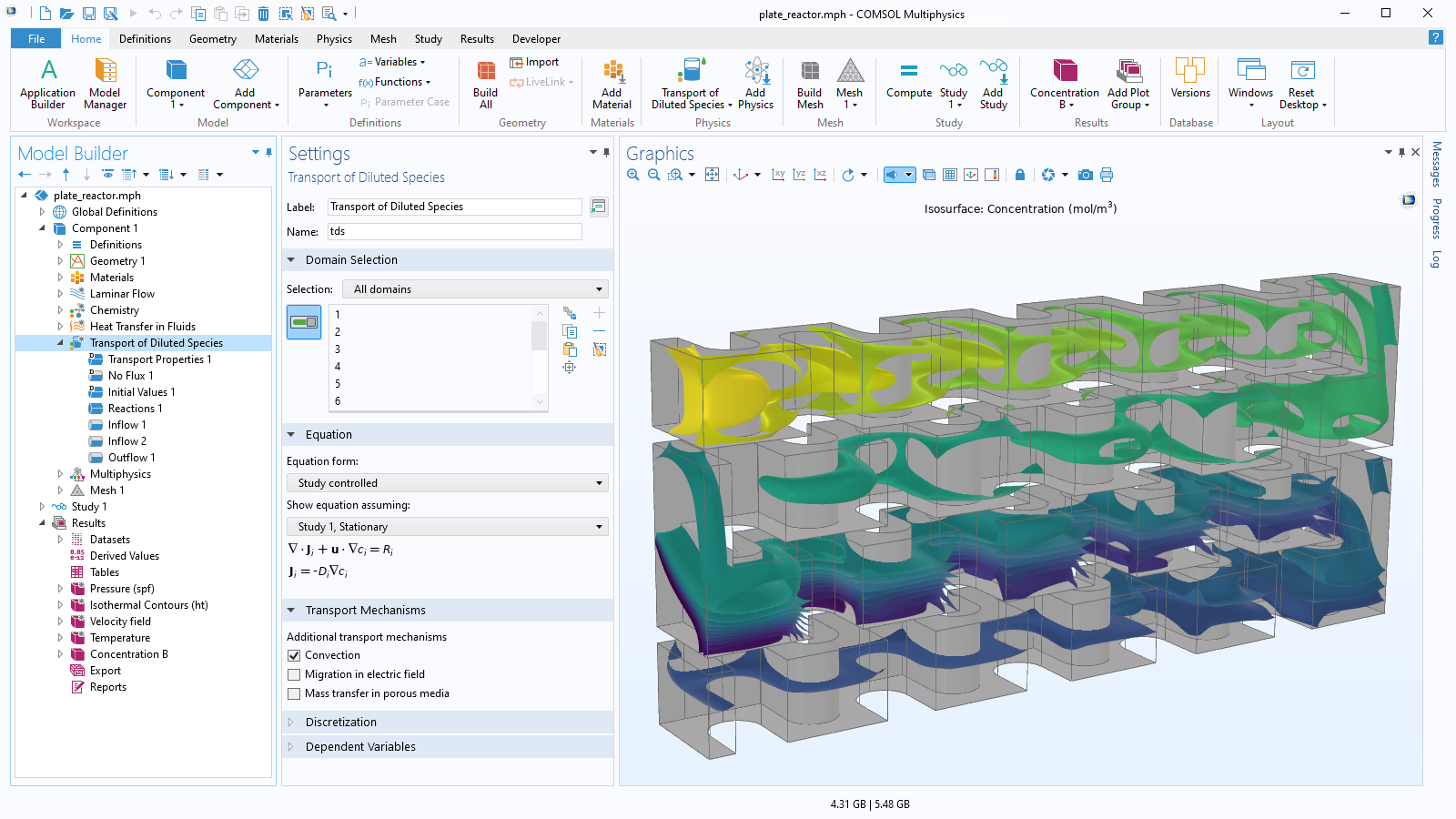

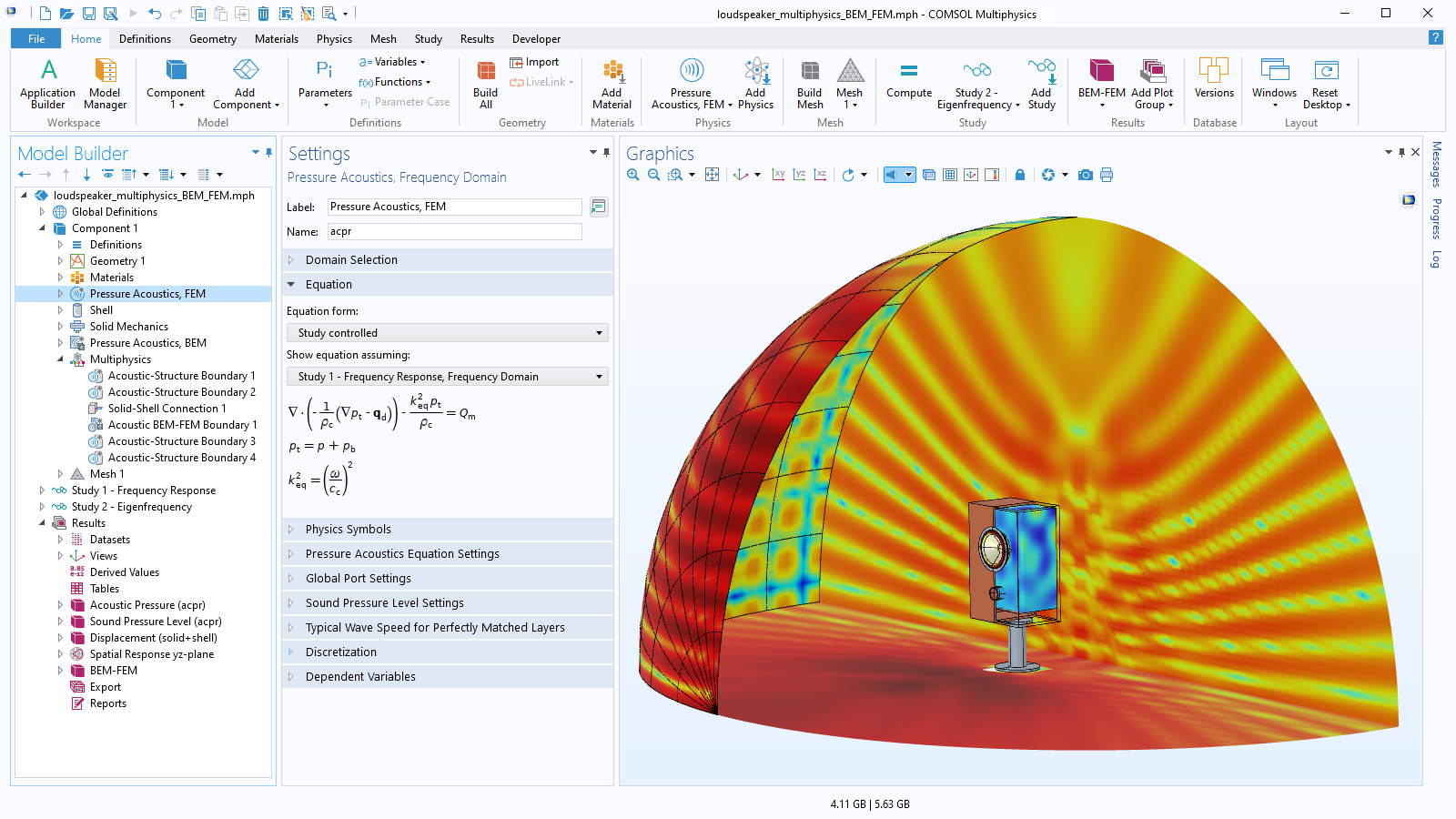

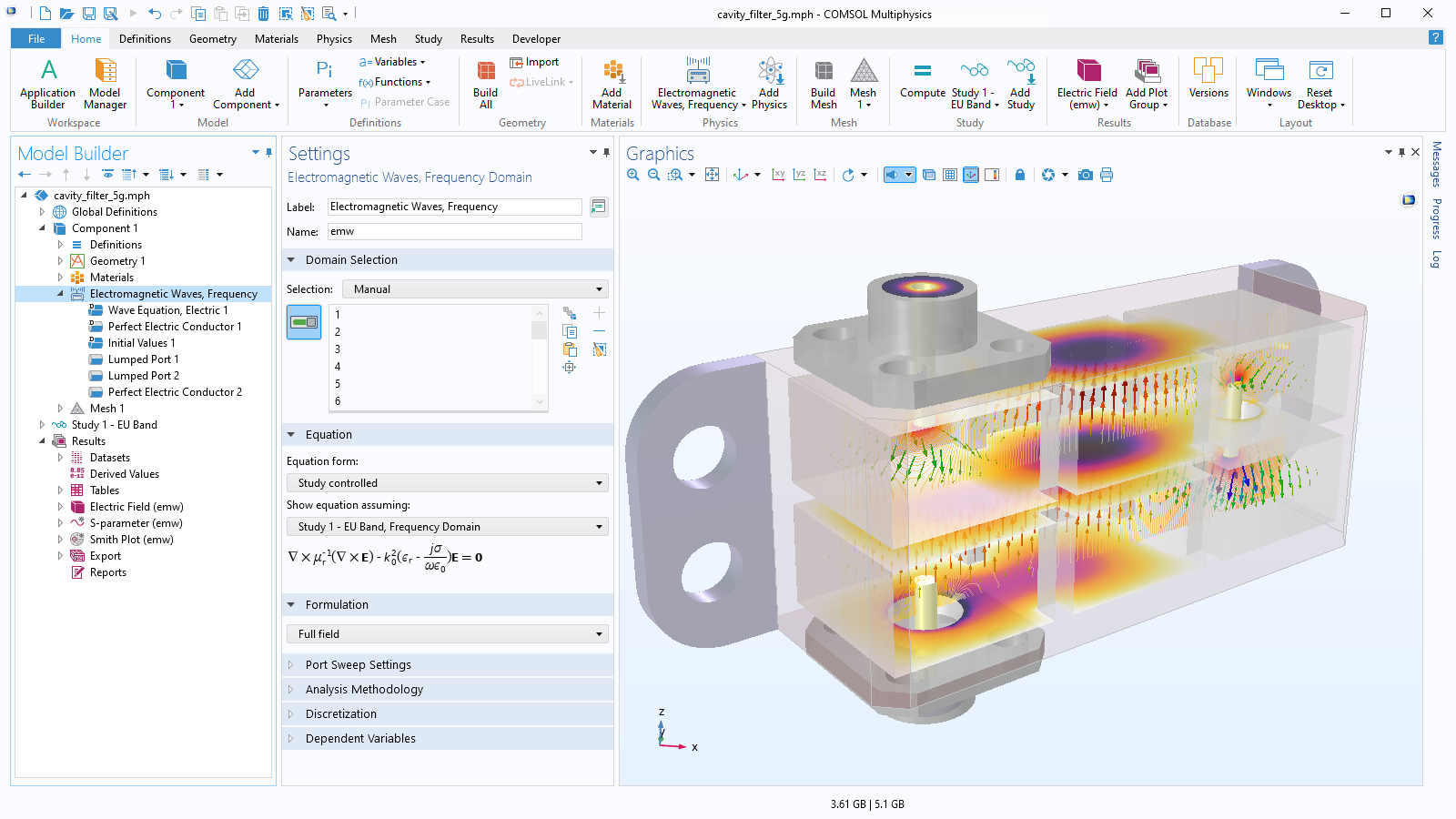

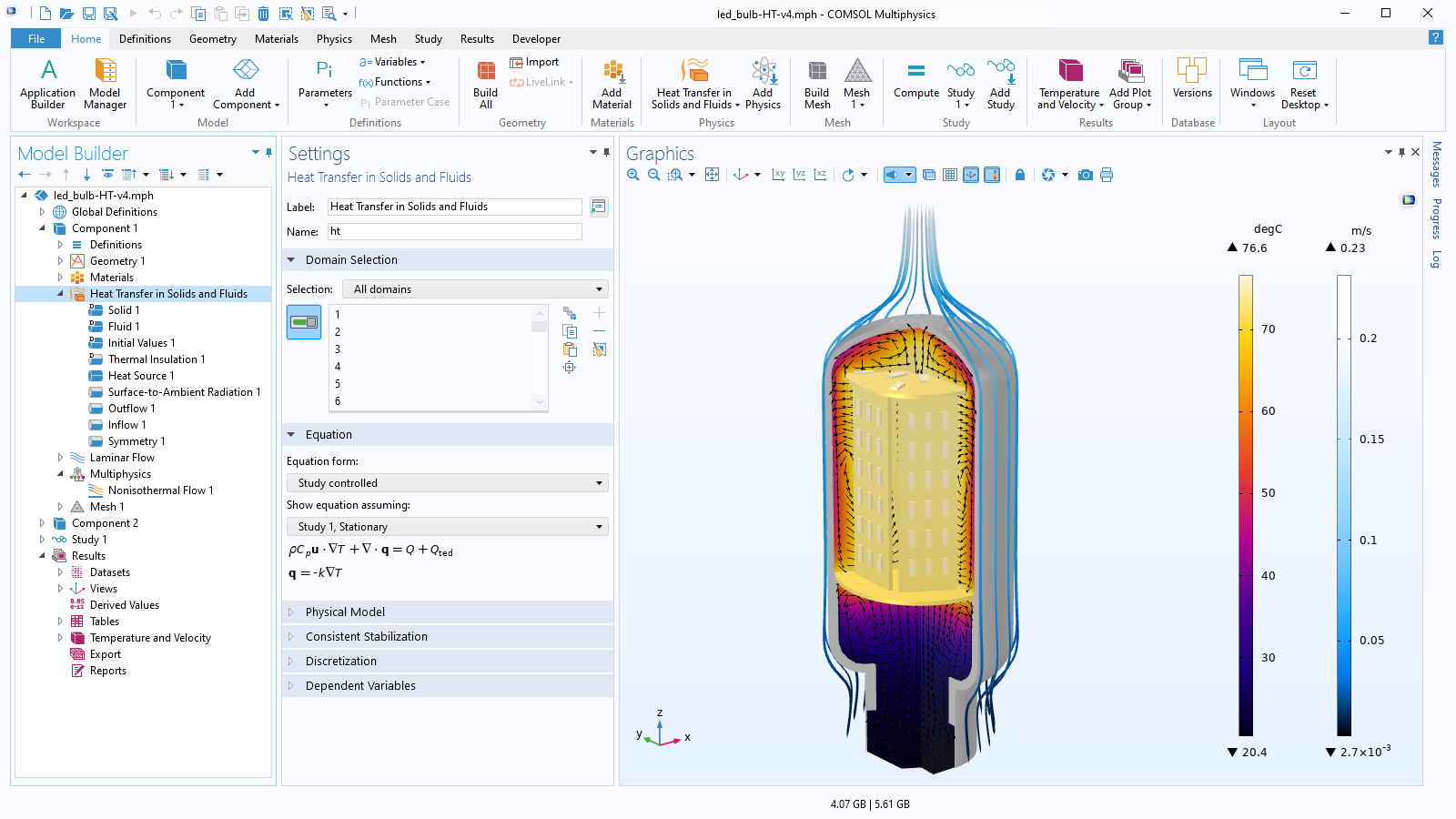

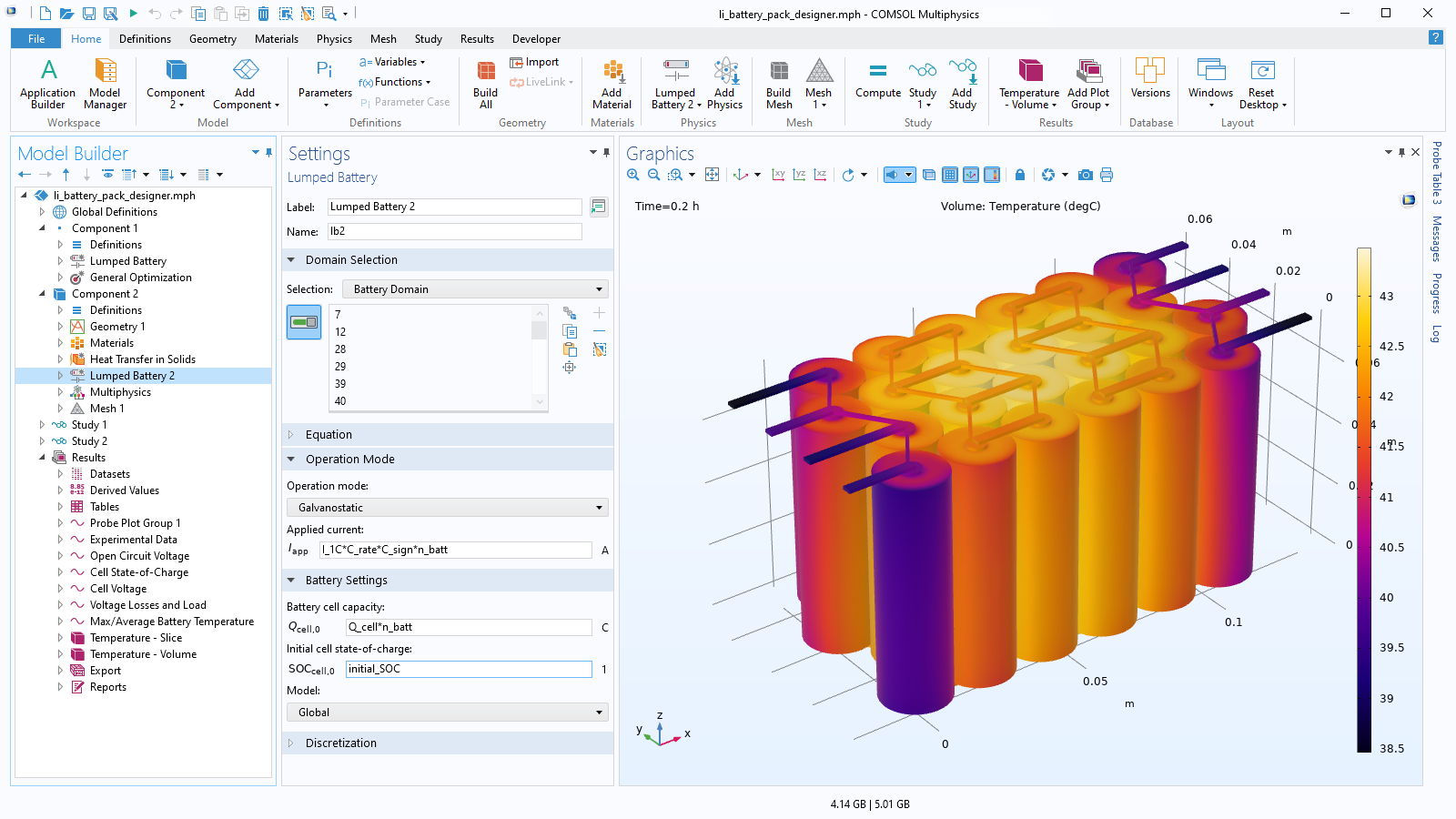

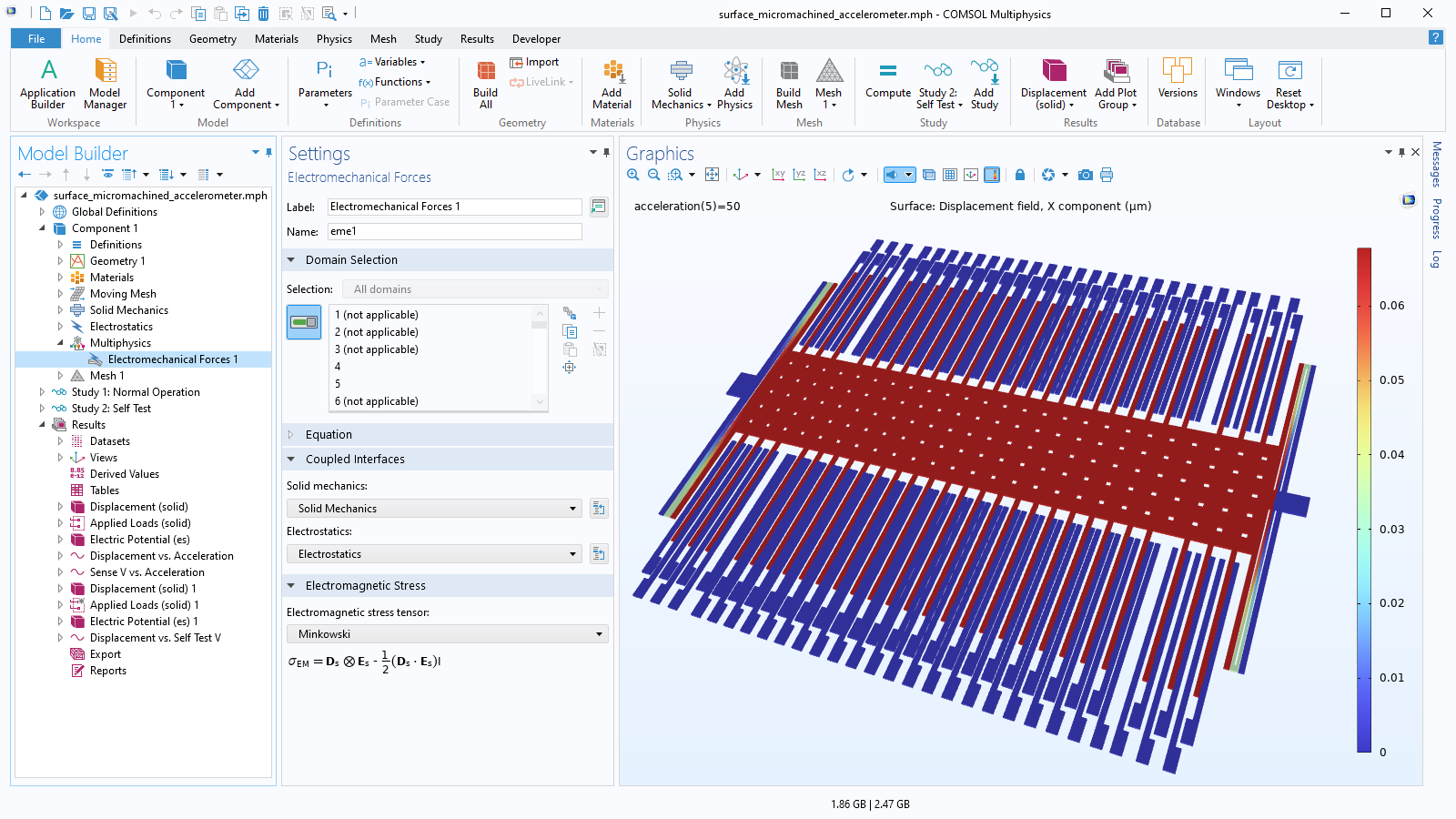

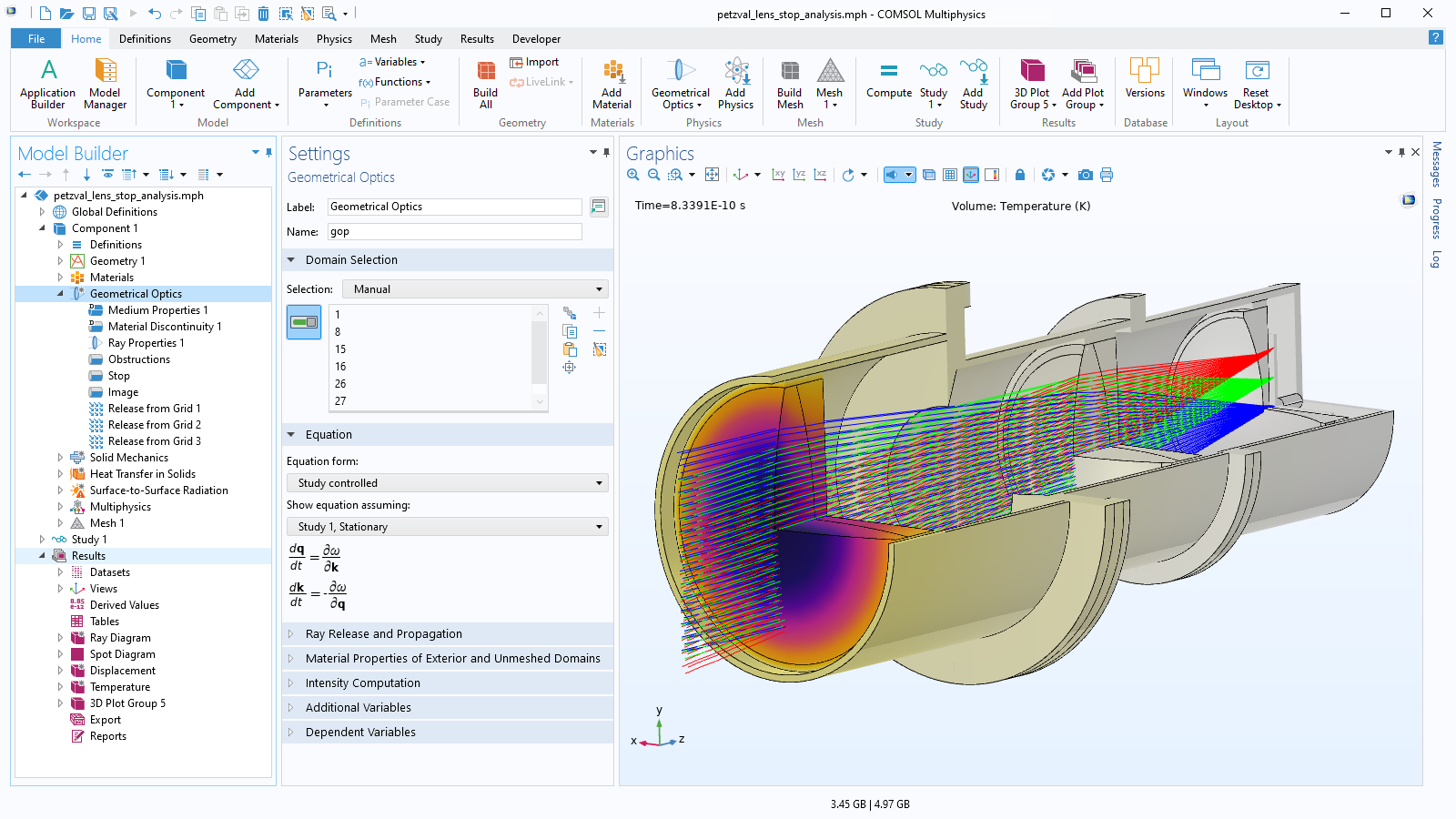

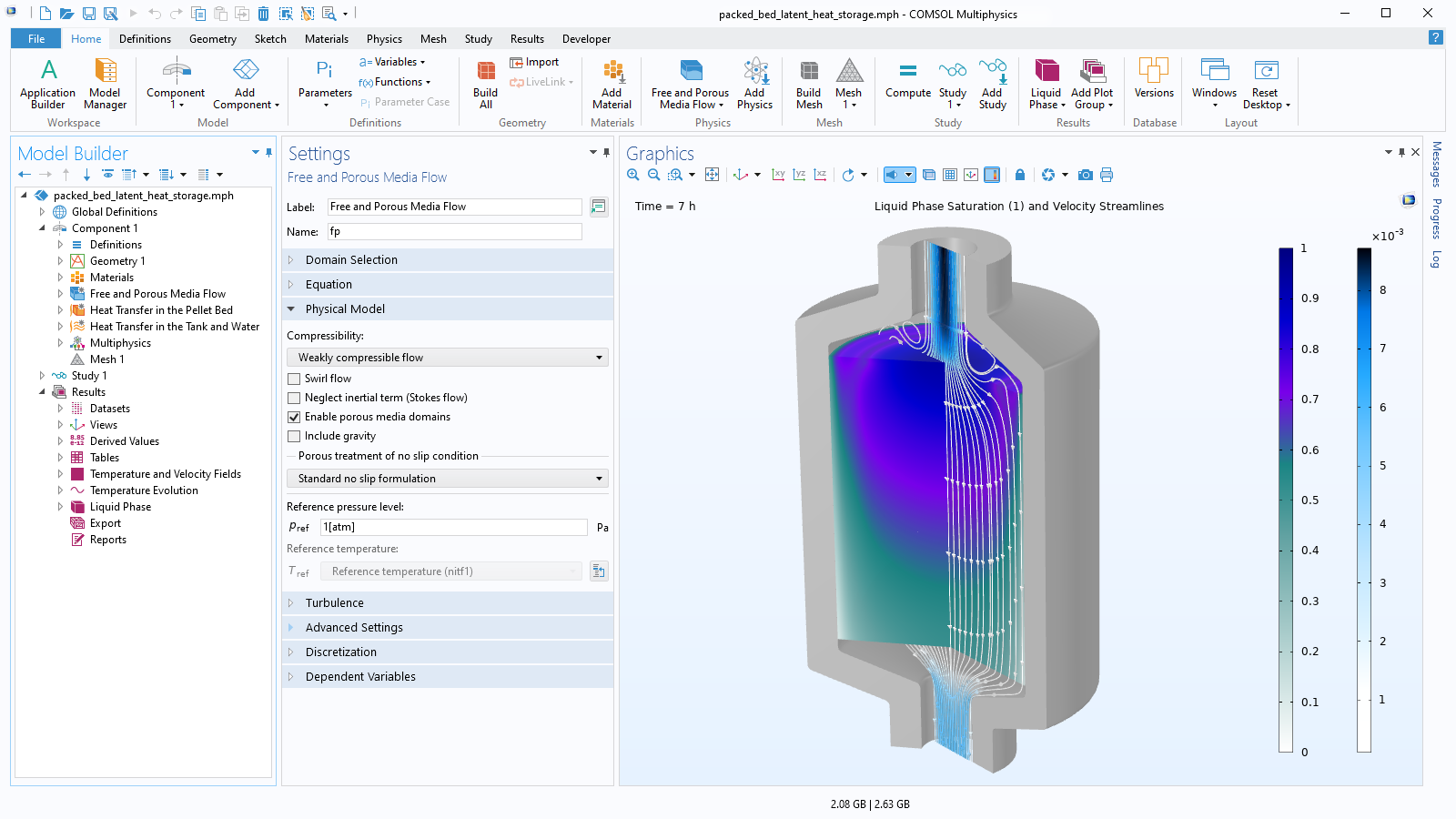

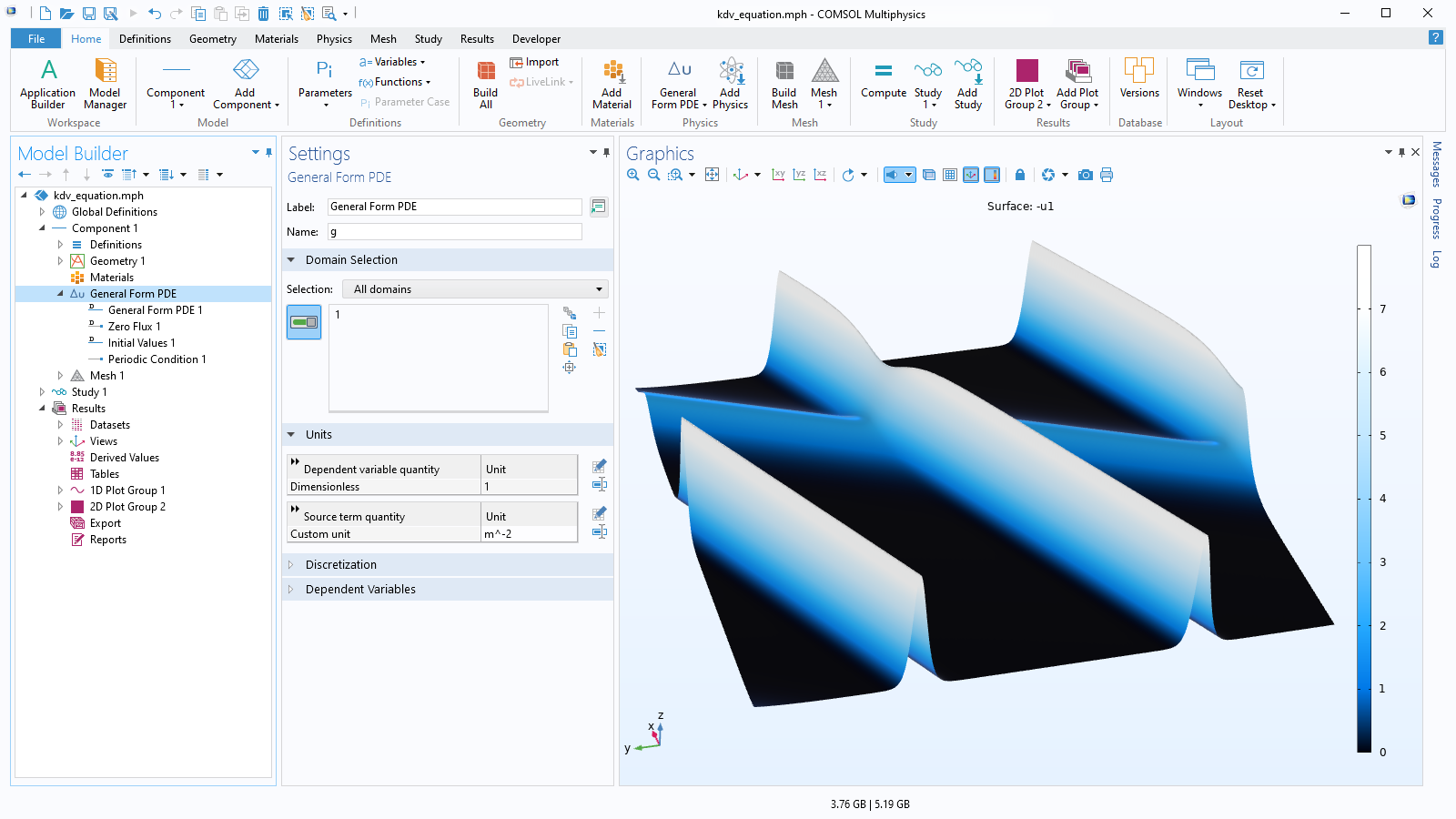

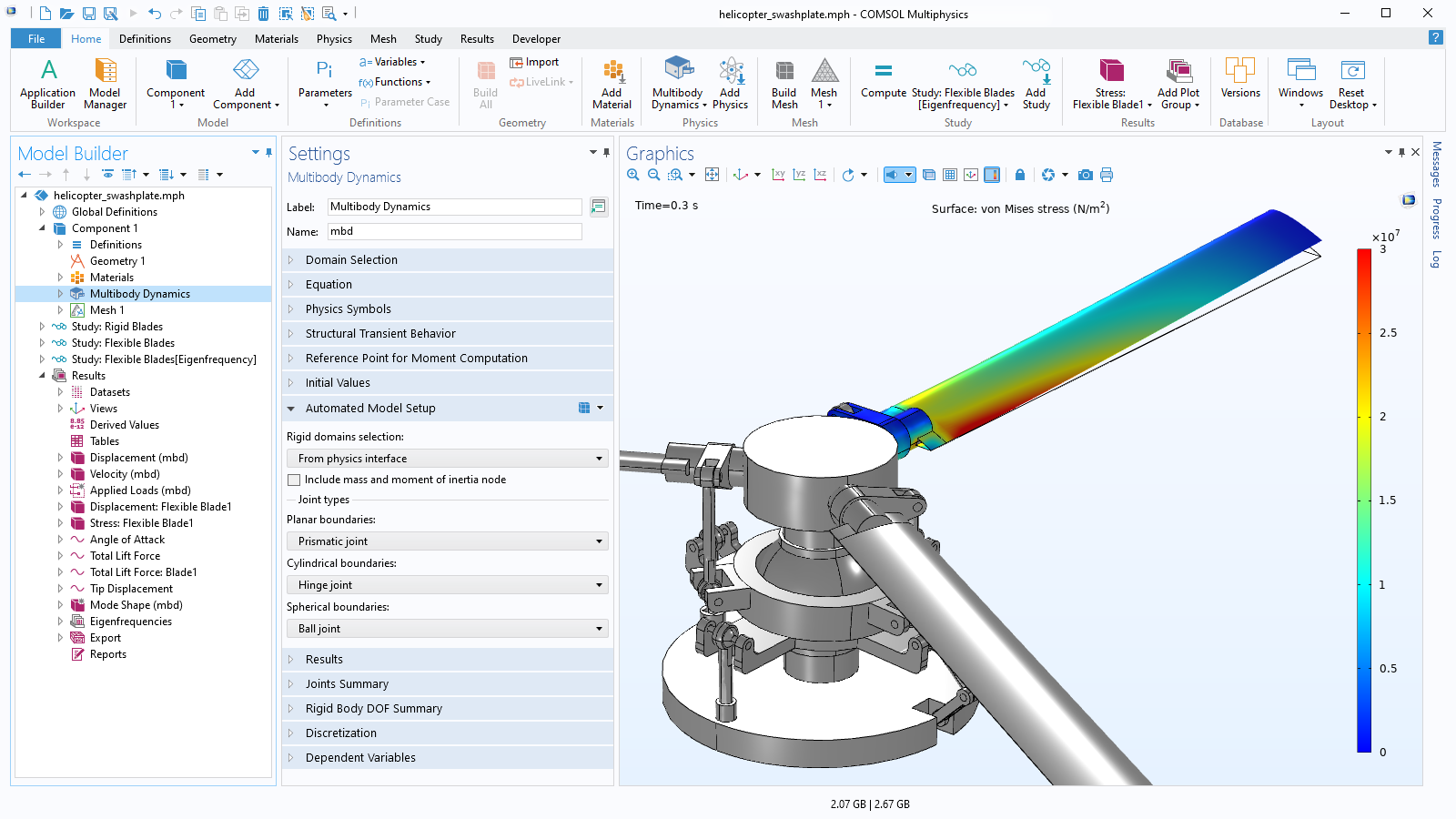

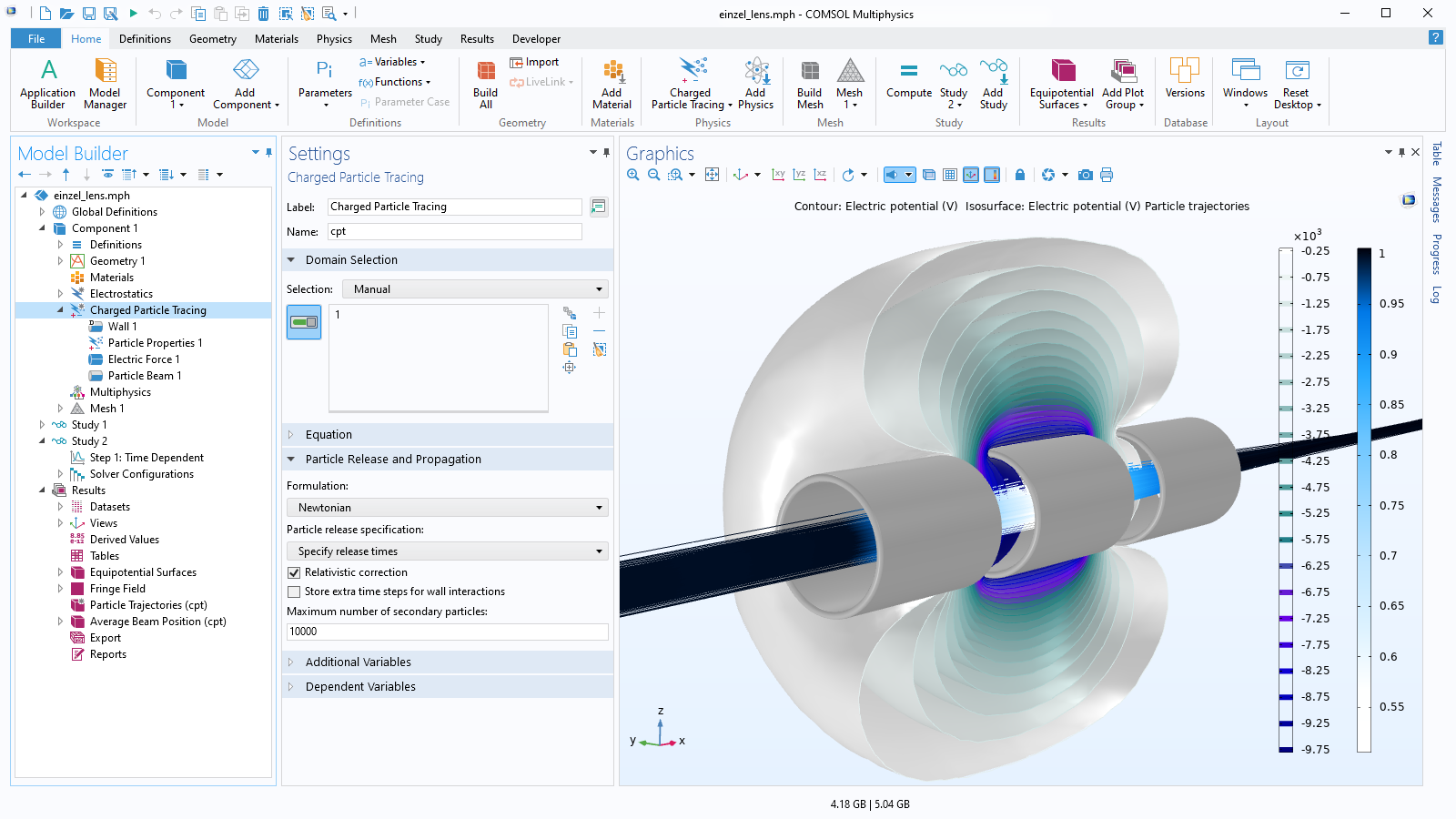

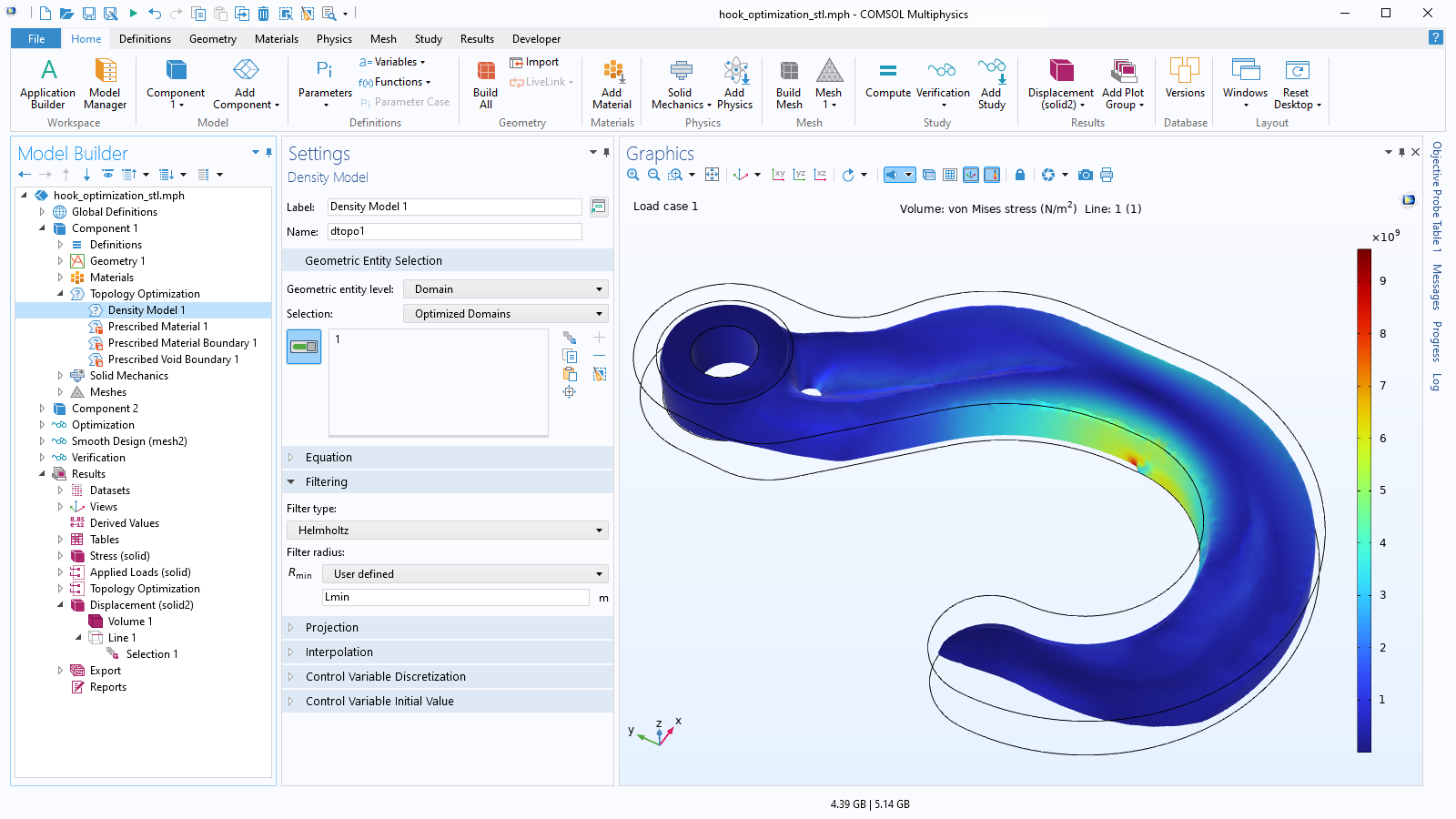

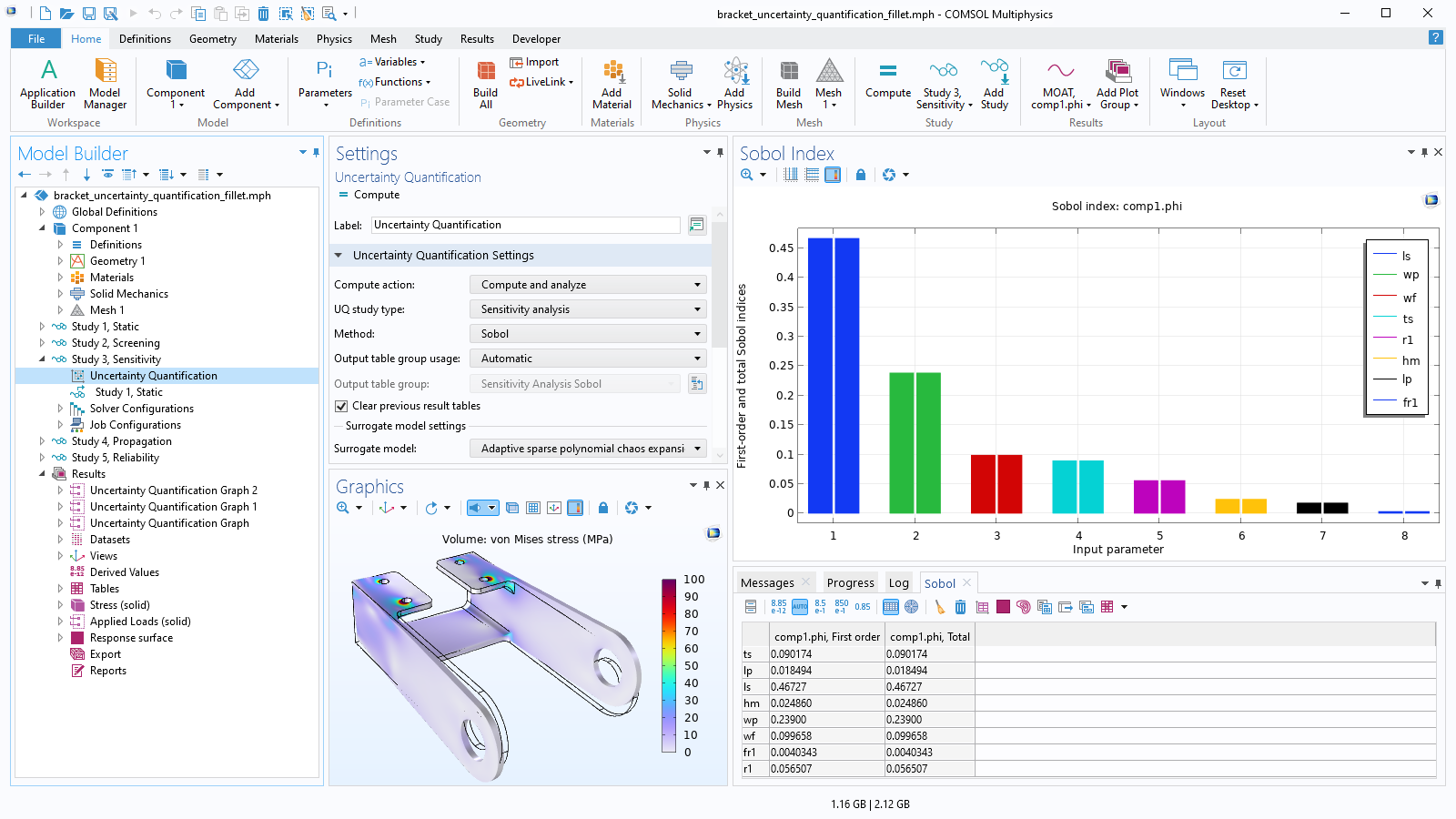

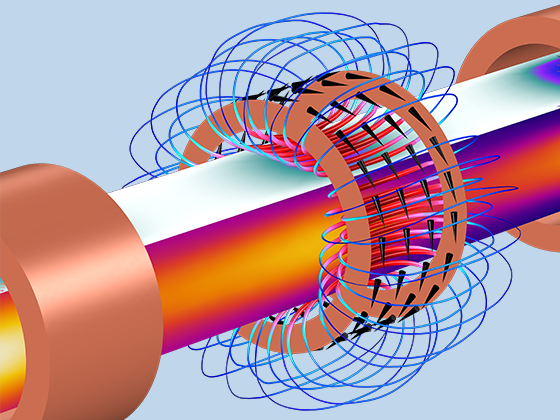

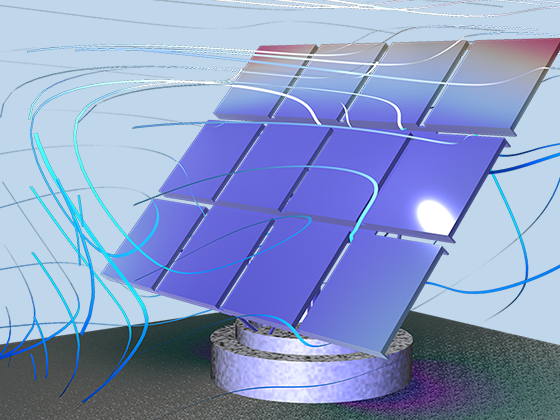

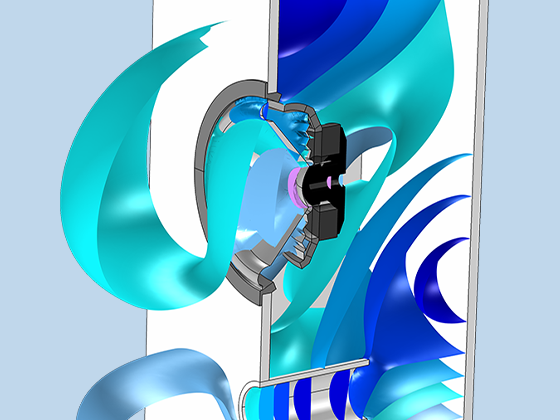

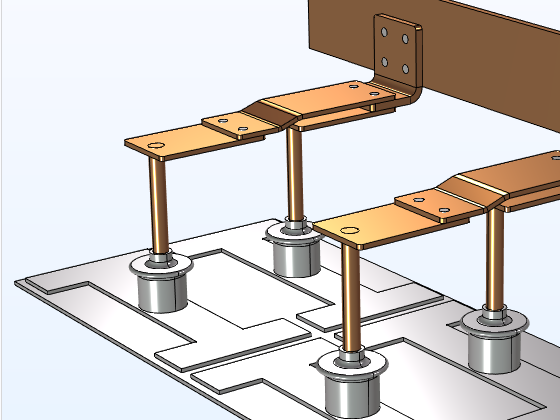

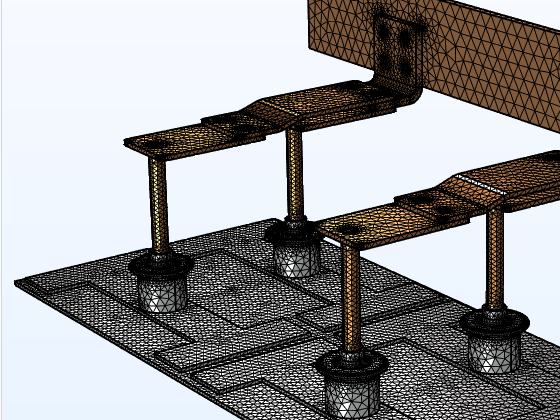

マルチフィジックスは, 多くの場合, 設計やプロセスを正確にモデル化するために必要とされます. COMSOL Multiphysics® のユーザーは, シミュレーションソフトウェアに一般的に付随する制限的な性質から解放され, モデルのあらゆる面に対して完全な制御を行うことができます. いくつもの物理現象を組み合わせることができるので, 従来のアプローチでは不可能, または非常に困難だったシミュレーションを創造的に実行することができます. さらにカスタマイズしたい場合は, ユーザー定義の物理学的記述と, それに関連する方程式や式をユーザーインターフェースに直接入力できます.

正確なマルチフィジックスモデルは, 想定される幅広い動作条件と物理的効果を考慮しています. これによりモデルを使用して, 現実的な動作条件でのプロセスやデバイスを, 理解, 設計, 最適化することができます.